Lesson 8: Home Heating Systems

The links below provide an outline of the material for this lesson. Be sure to carefully read through the entire lesson before returning to Canvas to submit your assignments.

Introduction

Welcome to Lesson 8!

More than 90 million single-family, multi-family, and mobile-home households encompass the residential sector. Households use energy to cool and heat their homes, to heat water, and to operate many appliances such as refrigerators, stoves, televisions, and hot tubs.

Nearly half of the energy used at home is for space heating. Conventional space heating systems in the U.S. emit a billion tons of carbon dioxide (CO2) and about 12 % of the sulfur dioxide and nitrogen oxides. Reducing the use of conventional energy sources for heating is the single most effective way you can reduce global environmental problems.

Look at the graph below to see how energy is used in U.S. households.

| How Energy is Used | Amount of Energy Used |

|---|---|

| Other Appliances and Lighting | 23% |

| Refrigerators | 5% |

| Water Heating | 17% |

| Electric Air Conditioning | 8% |

| Space Heating | 47% |

The energy sources utilized by the residential sector include electricity, natural gas, fuel oil, kerosene, liquefied petroleum gas (propane), coal, wood, and other renewable sources such as solar energy.

Look at the graph below to see the primary fuel used by U.S. households.

| Primary Fuel Used by U.S. Households | Amount of Fuel Used |

|---|---|

| Natural Gas | 55% |

| Electricity | 29% |

| LPG | 5% |

| Other | 0% |

| Fuel Oil | 8% |

| Kerosene | 1% |

| Wood | 2% |

Lesson 8 Objectives

Upon Completion of this lesson, students will be able to:

- explain the operating principles of various types of heating systems;

- list the main advantages and disadvantages of various heating systems;

- explain the energy efficiencies of each of these heating systems; and

- describe ways to improve the energy efficiency of the heating systems.

Checklist for Lesson 8

Here is your "to do" list for this week.

| Step | Activity | Access / Directions |

|---|---|---|

| 1 | Read the online lesson | Lesson 8a - Comparison of Home Heating Systems Lesson 8b - Cooling and Heating |

| 2 | Review | Lesson 8 - Review and Extra Resources (supplemental materials that are optional...but informative!). |

| 3 | Take |

Lesson 8 - Quiz (graded). The quiz is available in Canvas. |

See the Calendar tab in Canvas for due dates/times.

Questions?

If you have any questions, please post them to the General Course Questions forum in located in the Discussions tab in Canvas. I will check that discussion forum daily to respond. While you are visiting the discussion board, feel free to post your own responses to questions posted by others - this way, you might help a classmate!

Lesson 8a: Comparison of Home Heating Systems

The following pages in Section A of Lesson 8 will cover comparisons of home heating systems.

Central Heating Systems

Home heating systems are classified based on the fuel and/or the method by which the heat is transferred and distributed into the house:

- Furnaces, boilers, or electric resistance heat powered by conventional fuels supply most of the heating in homes and commercial buildings today.

- Heat pumps are used to a lesser (but increasing) extent to provide space heating.

Most newer homes are heated using central heating systems. Those without central heating systems utilize electric baseboard heaters or, in some cases, in-the-wall or in-floor gas heaters or radiant heat.

Instructions: Move your cursor over the numbers below and click to see the characteristics of a central heating system:

Central Ducted Air Systems

Ducted air systems are the most common type of central heating and cooling used. If a home has a central air conditioner, heat pump, or furnace, it is a ducted air system. There are two main types: Forced-air Heating Systems and Gravity Heating Systems.

Forced Air Heating Systems

Almost 35 million homes in America are heated by natural gas-fired, forced-air heating systems- by far the most popular form of central heating.

With a forced-air system, a furnace warms air, an air conditioner cools air, or a heat pump either warms or cools air, then a blower forces the air through the system. Therefore, the same duct system can be used for both heating and cooling.

Below are images of the main components of a forced air heating system. Can you identify each? Drag and drop the image onto its name.

In a forced-air heating system, room air (cooler) is drawn by a fan or a blower through return air registers and ductwork, and passes through a filter (to remove any dust particles) into a furnace, where the air is heated. The warmed air is then blown back to rooms through a system of supply ducts and registers.

Click on the “play” button below to see how a forced-air heating system works.

Gravity Heating System

With a gravity furnace, convection currents (caused by the natural tendency of heated air to rise) carry heated air through the system from a furnace that is located on or below the main floor level. Gravity systems, somewhat older, do not have blowers, and tend to have very large air ducts; they can only deliver warmed air.

Press the "play" button below to see how a gravity heating system works.

In gravity heating systems, the ducts are larger than forced-air heating systems, and only warm air travels through them.

Conventional Furnaces

Most furnaces are gas-fired, but other fuels include oil, coal, wood, and electricity.

With a conventional furnace, natural gas is piped to a burner located inside a combustion chamber. There, the gas is mixed with air, then ignited by a pilot light, a spark, or a similar device controlled by a thermostat. The flame heats up a metal box—the heat exchanger—where room air is heated as it flows through. Exhaust gases given off by burners vent outside through a flue that goes up through the roof or, with newer high-efficiency models, out through a wall.

Instructions: Press the play button to see how a gas furnace works, and then answer the question that follows.

An electric furnace uses heating elements rather than burners to heat in the heat exchanger.

Instructions: Press the "play" button to see how an electrical furnace works, and then answer the question that follows.

Click here to open a text description of How an Electrical Furnace Works

Heat Distribution

As you may recall from the “drag ‘n drop” activity on the Central Ducted Air Systems page, the main components of a forced-air heating system include the furnace, main duct, branches, and registers.

In a hot-air system, warm air is distributed via a main duct and a series of branches that lead to individual rooms or zones. Where the branches meet the main duct, heat is controlled by dampers (act as valves for air flow), which open or close to release or block heat from entry. These dampers, usually motorized, are run by thermostatic controls at each zone. Individual registers may also be closed to block heat, but this is a less efficient use of the energy and heat produced than when there are thermostatic or automatic controls.

An upward-flow furnace draws cold air in through the bottom and sends heated air out the top. Upward-flow furnaces are often used in houses that have basements or that deliver heat through overhead ductwork.

A downward-flow or counter-flow furnace draws cool return air through the top and delivers heated air out the bottom. This type is favored where there is no basement, or where air ducts are located in the floor.

A forced-air heating system can be combined with air conditioning (for cooling), a humidifier (for maintaining proper moisture balance), and an air filter (for purifying the air). Ductwork is generally metal, wrapped with insulation to help keep heat in. In some cases, flexible insulation-style ductwork is preferred. This system has several advantages and disadvantages, as described below.

Advantages

- Air ducts and registers distribute heat from a central furnace, providing rapid heat delivery.

- The system can also be used to filter and humidify the household air, to provide central air conditioning.

- The system circulates air for ventilation.

Disadvantages

- Air coming from the heating registers sometimes feels cool (especially with certain heat pumps), even when it is warmer than the room temperature.

- There can also be short bursts of very hot air, especially with oversized units.

- Ductwork may transmit furnace noise, and can circulate dust and odors throughout the house.

- Ducts are also notoriously leaky, typically raising a home's heating costs by 20% to 30%.

Radiant Heating Systems - Baseboards

Baseboard Radiators

In the baseboard hydronic heating systems (shown below), water is heated in a gas-fired or oil-fired furnace located in the basement. The heated water is distributed through pipes into baseboards in various rooms. The heat is then delivered through radiation and convection. Although these are called radiant heating systems, most of the heat delivered is by convection. Heat delivery into rooms or zones can be controlled by flaps or louvers.

A picture of a baseboard heater is shown below. Closely spaced metallic sheets called “fins” increase the surface area for efficient heat transfer into the room.

Advantages and Disadvantages of Radiant Baseboard Heating

| Advantages | Disadvantages |

|---|---|

| In general, it operates quietly. | Cannot be used for cooling. |

| It delivers constant heat and doesn't stir up allergens or dust. | High installation costs. |

| Because it warms people and objects rather than just air, it feels warm even if a door is opened or a room is somewhat drafty or slightly cooler than normal. | Interference with furniture placement. |

| There is less heat loss (waste) compared to a forced air system because there is no leakage. | Air entrapment can reduce efficiency. |

Radiant Heating Systems - Floors

Types of Radiant Floor Heat

There are three types of radiant floor heat:

- Radiant air floors (air is the heat-carrying medium)

- Electric radiant floors

- Hot water (hydronic) radiant floors.

Instructions: Compare conventional baseboard heating to radiant floor heat, by clicking on the button below. (14 seconds and 11 seconds)

Finish: Comparison of Home Heating Systems

Types of Installation

All three types of radiant floor heat (air, electric, hot water) can be further subdivided by the type of installation:

- Those that make use of the large thermal mass of a concrete slab floor or lightweight concrete over a wooden subfloor (these are called “wet installations”)

- Those in which the installer “sandwiches” the radiant floor tubing between two layers of plywood or attaches the tubing under the finished floor or subfloor (“dry installations”)

Cost Effectiveness

Radiant Air Floors

Because air cannot hold large amounts of heat, radiant air floors are not cost-effective in residential applications and are seldom installed.

Electric radiant floors

Electric radiant floors are usually only cost-effective if your electric utility company offers time-of-use rates. Time-of-use rates allow you to “charge” the concrete floor with heat during off-peak hours (approximately 9 p.m. to 6 a.m.). If the floor's thermal mass is large enough, the heat stored in it will keep the house comfortable for eight to ten hours without any further electrical input. This practice saves a considerable number of energy dollars compared to heating at peak electric rates during the day.

Instructions: Press the play button to observe how a concrete floor is charged during time-of-use rates. (1 minute 16 seconds)

Hydronic systems

Hydronic (liquid) systems, popular and cost-effective systems for heating-dominated climates, have been in extensive use in Europe for decades.

Hydronic radiant floor systems pump heated water from a boiler through tubing laid in a pattern underneath the floor. The temperature in each room is controlled by regulating the flow of hot water through each tubing loop via a system of zoning valves or pumps and thermostats.

Instructions: Press the play button to see how a hydronic radiant floor system works. (9 seconds)

Installation

Wet installations are the oldest form of modern radiant floor systems. In a wet installation, the tubing is embedded in the concrete foundation slab, or in a lightweight concrete slab on top of a subfloor, or over a previously poured slab.

A new generation of in-floor hydronic heating that employs corrosion-proof, hot-water tubing has enjoyed widespread popularity in recent years. With this type of system, heat is evenly distributed and floors are warm under foot. A variety of heating equipment may heat water: natural gas or propane water heater or boiler, electric boiler, wood boiler, heat pump, solar collector, or even geothermal energy.

Tubing for a hydronic system may be installed in a conventional concrete slab or in a lightweight, gypsum-cement slab. It can also be stapled to the undersides of subflooring as shown in the image below:

A new generation of hydronic heating: This photograph depicts corrosion-proof, hot-water tubing stapled to the underside of subflooring.

Radiant Floor Coverings

Although ceramic tile is the most common floor covering for radiant floor heating, almost any floor covering can be used. However, some perform better than others. Common floor coverings like vinyl and linoleum sheet goods, carpeting, wood, or bare concrete are often specified.

- Carpeting

It is wise to always remember that anything that can insulate the floor also reduces or slows the heat entering the space from the floor system, which in turn increases fuel consumption. If carpeting is required, a thin carpet with dense padding is preferred. If some rooms, but not all, will have a floor covering, then those rooms should have a separate tubing loop to make the system heat these spaces more efficiently, because the water flowing under the covered floor will need to be hotter to compensate for the floor covering. - Wood Flooring

Most radiant floor references also recommend using laminated wood flooring instead of solid wood, thus reducing the possibility of the wood shrinking and cracking from the drying effects of the heat. While solid wood flooring can be used, the installer is strongly advised to be very familiar with radiant floor systems before attempting to install natural wood flooring over a radiant floor system. Most manufacturers and manuals relating to radiant floors offer guidelines to help you resolve these issues.

Instructions: Dr. P. is doing some remodeling and needs to purchase new flooring. Assuming his home uses radiant heat, help him select the most appropriate flooring option.

Radiant Floor Tubing

There are various types of tubing used in Radiant floor heating systems.

- Copper or Steel Tubing - Older radiant floor systems used either copper or steel tubing embedded in the concrete floors. Unless the builder coated the tubing with a protective compound, a chemical reaction between the metal and the concrete often led to corrosion of the tubing, and to eventual leaks.

- PEX or Rubber Tubing - Major manufacturers of hydronic radiant floor systems now use cross-linked polyethylene (PEX) or rubber tubing with an oxygen diffusion barrier. These materials have proven themselves to be more reliable than the older choices in tubing. Fluid additives also help protect the system from corrosion.

- Defective Tubing - There have been recent reports of problems with rubber tubing produced by one chemical manufacturer. Leaks develop at the metal connections or fittings, and, in some cases, the tubing becomes rigid and brittle. It is still not clear what causes this problem, but, theoretically, excessively high water temperatures may be to blame. Tightening the connections and clamps only temporarily fixes the leaks. Remember, this problem only concerns a specific brand of rubber tubing; it does not have anything to do with the PEX tubing, which has performed very reliably for many decades. Since the price of copper tubing is considerably lower now than several years ago, it is again gaining some popularity because of its superior heat transfer abilities over plastic-based tubing.

How Radiant Heat Systems are Controlled

Instructions: Click on the hot spots in the image below to find out how radiant heat systems are controlled.

Advantages and Disadvantages of Radiant Floor Heating Systems

| Advantages | Disadvantages |

|---|---|

| Radiant floor systems allow even heating throughout the whole floor, not just in localized spots as with wood stoves, hot air systems, and other types of radiators. | Does not respond quickly to temperature settings. |

| The room heats from the bottom up, warming the feet and body first. | Relatively expensive to install but can save money in the long run. |

| Radiant floor heating also eliminates the draft, dust, and allergen problems associated with forced-air heating systems. | Requires professional installers. |

| With radiant floor heating, you may be able to set the thermostat several degrees lower, relative to other types of central heating systems. | |

| There are no heat registers or radiators to obstruct furniture arrangements and interior design plans. |

Direct or In-Situ Heating Systems

Instead of generating heated air or water at a central location and then distributing it throughout the home, some systems generate heat where it is needed locally. The most common method is electric baseboard heat. Other ways include kerosene heat; wood-burning stoves; and fireplaces burning wood, coal, or natural gas. These systems can heat the whole house, part of the house, or a single room.

Electric Resistance Heat

Electric resistance heating converts nearly 100 percent of the energy in the electricity to heat. However, most electricity is produced from oil, gas, or coal generators that convert only about 30 percent of the fuel's energy into electricity. Because of electricity's generation and transmission losses, electric heat is often more expensive than heat produced in the home with combustion appliances such as natural gas, propane, and oil furnaces.

Electric resistance heat can be supplied by centralized forced-air furnaces or by zonal heaters in each room, both of which can be composed of a variety of heater types.

- Zonal heaters distribute electric resistance heat more efficiently than electric furnaces because you set room temperatures according to occupancy.

- Zonal heaters have no ducts (unlike electric furnaces) that can lose heat before it reaches the room.

- Electric furnaces can accommodate central cooling more easily than zonal electric heating because the air conditioner can share the furnace's ducts.

- Electric resistance heat can be provided by electric baseboard heaters, electric wall heaters, electric radiant heat, electric space heaters, electric furnaces, or electric thermal storage systems.

| Type of Heater | Description | Method of Heating | Installation | Advantages / Disadvantages |

|---|---|---|---|---|

| Baseboard Heaters | Zonal heaters controlled by thermostats located in each room. Contain electric heating elements encased in metal pipes, which are surrounded by aluminum fins to aid heat transfer and run the length of the baseboard heater's housing, or cabinet. | Convection and radiation. As air within the heater is warmed, it rises into the room, and cooler air is drawn into the bottom of the heater. Some heat is also radiated from the pipe, fins, and housing. |

Usually installed underneath windows where the heater's rising warm air counteracts falling cool air from the cold window glass. Seldom located on interior walls because the standard heating practice is to supply heat at the home's perimeter where the greatest heat loss occurs. Should sit at least three-quarters of an inch (1.9 centimeters) above the floor or carpet, to allow the cooler air on the floor to flow under and through the radiator fins so it can be heated. Should also fit tightly to the wall to prevent the warm air from convecting behind it and streaking the wall with dust particles. |

The quality of baseboard heaters varies considerably. Cheaper models can be noisy and often give poor temperature control. Look for labels from Underwriter's Laboratories (UL) and the National Electrical Manufacturer's Association (NEMA). Compare warranties of the different models you are considering. |

| Wall Heaters | Consist of an electric element with a reflector behind it to reflect heat into the room, and usually a fan to move air through the heater. | Convection and radiation. | Usually installed on interior walls because installing them in an exterior wall makes that wall difficult to insulate. | ---------- |

| Radiant Heaters | Several types, including electrical heating cables (most common), gypsum ceiling panels and metal radiant panels (provide radiant heat faster than other types because they contain less material to warm up. | Radiation - radiate heat to the room's objects, including its people. For example, you can feel a ceiling-mounted radiant heating panel warming your head and shoulders if you stand underneath it. | Electric heating cables are imbedded in floors or ceilings; gypsum ceiling panels are already equipped with factory-imbedded heating cables; and metal radiant panels are ceiling-mounted. | Offers draft-free heating that is easily zoned. It occupies no interior space, allowing you complete freedom to place furniture without worrying about impeding air flow from registers or baseboard heaters. Manufacturers claim that radiant heat can provide comfort similar to other systems at lower indoor air temperatures, saving around 5 percent of space heating costs. Critics say that it can be difficult to control air temperature with a thermostat. The large heat-storage capacity of the concrete or plaster surrounding the heating cables may result in greater-than-normal fluctuations in the room air temperature, since it takes quite a while to heat up the storage mass. Also, some occupants complain about their heads being too warm in rooms that utilize ceiling radiant heat. Supplying heat at the ceiling or floor, which are locations that typically border the outdoors or unheated spaces, can result in greater heat losses. For example, if there are any flaws in a heated concrete slab or gaps in the ceiling insulation above heating elements, a large percent of the electric heat may escape to the outdoors without ever heating the home. |

| Space Heaters | Electric space heaters come in a wide variety of models, either built-in or portable. Portable space heaters, as well as many built-in space heaters for small rooms, have built-in thermostats. Larger rooms heated with built-in electric space heaters should have low-voltage thermostats installed in an area that maintains the room's average temperature. |

These heaters may have fans to circulate heated air, and may also be designed to transfer some of their heat by radiation. | All of these heaters must be given adequate clearance to allow air to circulate safely. | --------------- |

Fireplaces

Fireplaces are very commonly used in family rooms and other living areas to give a warm and cozy feeling. These fireplaces can be wood or natural-gas fired.

Generally, fireplaces transfer the heat by radiation, and hot combustion gases (carrying a lot of thermal energy) go out through the stack. Hot gases are lighter and rise up the chimney; a natural suction created by this flow draws the heated warm air from the room.

Most of the time, the warm air heated in the room by the main heating fuel is also drawn into the fireplace and goes up the chimney, resulting in a net loss of energy. It is estimated that about 75 percent of the heated air is lost through the chimney. However, many people still use fireplaces inefficiently.

Advantages and disadvantages of direct heating systems

| Advantages | Disadvantages |

|---|---|

| Generates heat at the point of use; no transmission losses. | Heats only certain parts of the home. |

| Inexpensive to purchase and install. | Cannot be used for cooling. |

| Easy local control in each room. | Takes up living room. |

| In well-insulated houses, it may be cheaper than other systems. | Generally less efficient than other central heating systems. |

Lesson 8b: Cooling and Heating

The following pages in Section B of Lesson 8 will cover cooling and heating.

Heat Movers

So far, we have discussed systems in which a fuel is burned and heat is produced and delivered into the home. In these systems, we buy all the energy, and (depending on the system) we reject or lose some heat to the surroundings, reducing the efficiency.

One of the ways in which we can improve the heating efficiency is to make use of the heat that is available outside, even on a cold winter day. On a cold winter day with outside temperature at 30ºF, the air still has more energy compared to air at 10 ºF or 5ºF. Air at any temperature above absolute zero (0ºK or -273 ºC) will have energy.

The higher the temperature of air, the higher its energy content. This energy can be transferred to the interior.

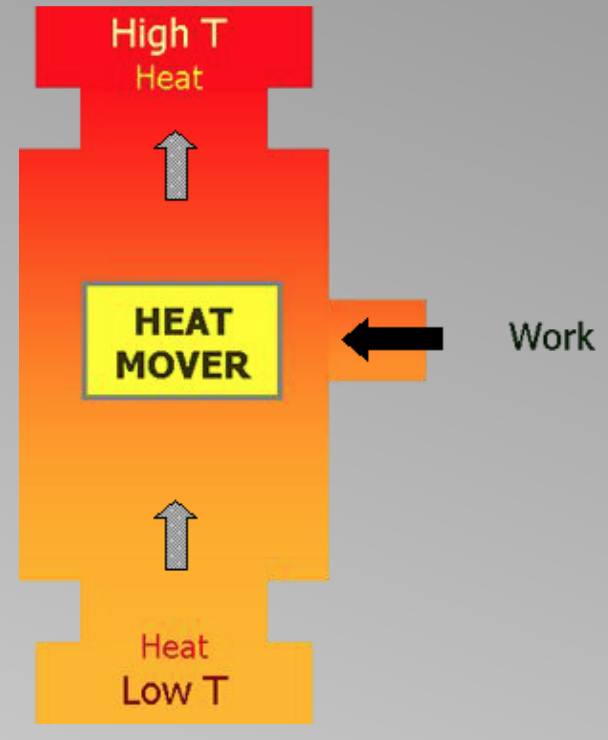

Heat Pumps

Under natural circumstances, heat only flows from high temperatures to low temperatures. In order to move heat from a low temperature environment to a high temperature environment, work needs to be done (or rather energy needs to be spent).

A device that moves the heat from a low temperature environment to a high temperature environment is called a heat mover.

An example of a heat mover is a heat pump. A heat pump is a heating/cooling system and also a forced-air system. Cooled (and sometimes humidified or electronically cleaned) air is usually delivered through the same ductwork and registers used by heated air.

A heat pump uses air-conditioning principles to extract heat from one place and deliver it to another, and vice versa. In addition to expelling heat from indoors, the system can be reversed to heat the home in the winter. Thus, a heat pump is a device that moves heat from a low-temperature to a high-temperature environment with the help of work that is put in.

Heat pumps are classified based on the low-temperature heat source:

- Air-source heat pump or Air-to-air heat pump. Heat is transferred from the low-temperature air outside to the high-temperature interior.

- Ground-source heat pump or Ground-to-air heat pump. The earth is used as a heat sink in the summer and a heat source in the winter; the pump relies on the relative warmth of the earth for its heating and cooling production.

- Water-source heat pump or Water-to-air heat pump. Heat is transferred from low-temperature water outside (from a pond or a lake) to a high-temperature interior.

An air conditioner is a cooling system and also a forced-air system. It runs on electricity and removes heat from the air with basic refrigeration principles.

Air-Source Heat Pump or Air-to-Air Heat Pump

An air-source or air-to-air heat pump can provide both heating and cooling.

- In the winter, a heat pump extracts heat from outside air and delivers it indoors.

- On hot summer days, it works in reverse, extracting heat from room air and pumping it outdoors to cool the house.

Nearly all air-source and air-to-air heat pumps are powered by electricity. They have an outdoor compressor/ condenser unit that is connected with refrigerant-filled tubing to an indoor air handler. As the refrigerant moves through the tubing of the system, it completes a basic refrigeration cycle, warming or cooling the coils inside the air handler. The blower pulls in room air, circulates it across the coils, and pushes the air through ductwork back into rooms.

When extra heat is needed on particularly cold days, supplemental electric-resistance elements kick on inside the air handler to add warmth to the air that is passing through.

Instructions: Click on the hot spots below to find out how the heating cycle of an air-source heat pump works:

In the winter, a heat pump extracts heat from outside air and delivers it indoors. In the summer, the heat pump extracts heat from room air and pumps it outdoors to cool the house.

Instructions: Observe the heating and cooling cycles of a heat pump.

Heating Cycle

Cooling Cycle

The Balance Point

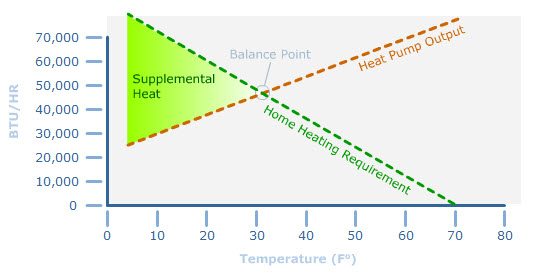

As we have learned, air-source and air-to-air heat pumps work by extracting heat from the outside air. These heat pumps require a backup system to supplement their heating ability when the outdoor temperature gets below a certain temperature.

As the outdoor temperature drops, the heating requirement of the house increases and the output of the heat pump decreases. At some point, the temperature of the home’s heating requirement and the heat pump output match. This temperature is called the balance point and usually falls between 30-45 degrees Fahrenheit. For any temperatures below the balance point, supplemental heat will be required.

To locate the balance point, the heating requirement (BTUs/h) of the house and the heat pump output (BTUs/h) are plotted against the changes in outside temperature. The place where the home heating requirement and heat pump output lines cross is the balance point.

Take a look at the graph of the Balance Point.

Efficiency of a Heat Pump

Efficiency of a heat pump is measured using a term Coefficient of Performance (COP), and it is the ratio of the useful heat that is pumped to a higher temperature, to a unit amount of work that is put in. We will look at COP in terms of air-source heat pumps.

A general expression for the efficiency of a heat engine can be written as:

Using the same logic that was used for heat engines, this expression becomes:

Where, Q Hot = Heat input at high temperature and Q cold= Heat rejected at low temperature. The expression can be rewritten as:

Note: Thot and Tcold must be expressed in the Kelvin Scale.

Air-Source Heat Pump or Air-to-Air Heat Pump Examples

Example 1

Calculate the ideal coefficient of performance (COP) for an air-to-air heat pump used to maintain the temperature of a house at 70 °F when the outside temperature is 30 °F.Solution:

First, convert the Fahrenheit temperatures to Celsius temperatures using this formula:

Next, convert the Celsius temperatures to Kelvin temperatures by adding 273.

Finally, use the formula from the previous screen to solve for the COP.

The example above shows that for every watt of power we use (and pay for) to drive this ideal heat pump, 13.3 W is delivered to the interior of the house and 12.3 from the outside (we don’t pay for this). This seems to be a deal that one cannot refuse. However, the theoretical maximum is never achieved in the real world. In practice, a COP in the range of 2 to 6 is typical. Even with this range, it is an excellent choice, because for every watt of power that we use, we transfer 1 to 5 additional watts from outside.

Example 2

Compare the ideal coefficients of performance of the same heat pump installed in State College, PA and Ann Arbor, MI when the inside temperature of a house is maintained at 70°F at both locations and the outside temperatures on a given day were 40°F and 15°F at State College and Ann Arbor, respectively.

| State College, PA | Ann Arbor, MI |

|---|---|

| Thot= 70 ºF = 21 ºC = 294 K | Thot= 70 ºF = 21ºC = 294 K |

| Tcold = 40 ºF = 4 ºC = 277 K | Tcold = 15 ºF = -9.4 ºC = 264 K |

| =17.3 | = 9.8 |

During a heating season, the heat pump's efficiency increases on mild days and decreases on cold days.

Ground Source (Geothermal) Heat Pumps

Ground-source or geothermal heat pumps (GHPs) are similar to the air-source heat pumps, except that the source of heat is the ground instead of outdoor air.

Instructions: Where does the heat in the ground come from? Press the “play” button and then answer the questions that follow.

As you observed in the animation, the earth absorbs and stores energy from the sun as heat, resulting in underground temperatures that range between 40–80ºF, depending on the location. These temperatures, which are located below the frost line (which is generally 4–5 feet in Pennsylvania), remain constant throughout the year.

The geothermal heat pumps (GHPs) use the earth as a heat sink in the summer and as a heat source in the winter, and therefore rely on the relative warmth of the earth for their heating and cooling production.

Through a system of underground pipes, they transfer heat from the warmer earth to the building in the winter, and take the heat from the building in the summer and discharge it into the cooler ground. Therefore, GHPs do not create heat; they move it from one area to another.

Operating Principle

The GHP system operates much like an air-source or air-to-air heat pump, except that:

- The outside tubing is buried to extract or discharge the heat in the ground;

- The compressor/condenser unit is inside rather than outside the house.

The GHP system also has additional valves to allow heat-exchange fluid (refrigerant) to follow two different paths: one for heating and one for cooling. The GHP takes heat from a warm area and exchanges the heat to a cooler area, and vice versa.

Instructions: Press the play button to see how a geothermal heat pump operates.

Classification of GHPs

Closed-Looped Systems

Horizontal

The horizontal type of installation is generally most cost-effective for residential installations, particularly for new construction where sufficient land is available. It requires trenches at least four feet deep.

Horizontal systems come in two types of layouts, the two pipes method and the slinky method.

Two Pipes

The most common horizontal layouts include:

Two Pipes Layout (Option 1) - One pipe buried at six feet, and another pipe buried at four feet.

Two Pipes Layout (Option 2) - Both pipes placed side-by-side at five feet in the ground in a two-foot wide trench.

The Slinky™ Method

The pipe is looped to allow more pipes in a shorter trench, which cuts down on installation costs and makes horizontal installation possible in areas not possible with conventional horizontal applications. Large commercial buildings and schools often use vertical systems because the land area required for horizontal loops would be prohibitive

Vertical

This type of system may be used when the soil is too shallow for trenching or when one does not want to disturb the existing landscaping.

For a vertical system, holes (approximately four inches in diameter) are drilled about 20 feet apart and 100 to 400 feet deep. Into these holes go two pipes that are connected at the bottom with a U-bend to form a loop. The vertical loops are connected with horizontal pipe (i.e., manifold), placed in trenches, and connected to the heat pump in the building

Pond

If a home has source surface water, such as a pond or lake, this type of loop design may be the most economical, since there is no need to dig a trench or a well for the pipes in the ground. In this type of system, the fluid circulates through polyethylene piping in a body of water, just as it does in the ground loops. The pipe may be coiled in a slinky shape to fit more of it into a given amount of space. This loop is recommended only if the water level never drops below six to eight feet at its lowest level, to assure sufficient heat-transfer capability. Pond loops used in a closed system result in no adverse impacts on the aquatic system.

Open-Loop Systems

This type of system uses well(s) or surface body water as the heat exchange fluid that circulates directly through the GHP system. Once it has circulated through the system, the water returns to the ground through the well, a recharge well, or a surface discharge. This option is obviously practical only where there is an adequate supply of relatively clean water, and all local codes and regulations regarding groundwater discharge are met.

Factors Affecting the Type of GHP Loop

Geothermal heat pumps (GHPs) can be used effectively almost anywhere in the country. However, the specific geological, hydrological, and spatial characteristics of a site determine the best type of ground loop for a specific location.

Instructions: Click on the hot spots in the image below to view the factors affecting the type of GHP Loop.

Benefits of a GHP System

Click on the benefit listed below to find out more information.

Typically, when heating systems or appliances are compared, all the costs that are incurred—purchase, installation, operation, and maintenance costs—can be combined into a life-cycle cost, the cost of ownership over a period of years. The table below compares the various types of central heating systems:

| Compare | Safety | Installation Cost | Operating Cost | Maintenance Cost | Life-Cycle Cost |

|---|---|---|---|---|---|

| Combustion-Based | A Concern | Moderate | Moderate | High | Moderate |

| Heat Pump | Excellent | Moderate | Moderate | Moderate | Moderate |

| Geothermal or Ground-Source Heat Pump | Excellent | High | Low | Low | Low |

Installation and Operating Costs of GHP Systems

On average, a geothermal heat pump (GHP) system costs about \$2,500 to \$3,500 per ton of capacity, or roughly \$7,500 to 10,000 for a 3-ton unit (typical residential size). In comparison, other systems would cost about \$4,000 with air conditioning.

When included in the mortgage, the homeowner has a positive cash flow from the beginning. For example, say that the extra \$3,500 will add \$30 per month to each mortgage payment. A 3,000 square-foot house in Oklahoma City (see below) has a verified average electric bill of \$60 per month, using a geothermal heat pump. This represents significant savings.

A system using horizontal ground loops will generally cost less than a system with vertical loops.

Geothermal heat pump installations in both new and existing homes can reduce energy consumption 25 to 75 percent compared to older or conventional replacement systems. Annual operating costs were also lowest with geothermal heat pumps. Add in the benefits of the desuperheater for hot water savings, and it's easy to see how a GHP system is the most efficient available.

Solar Energy for Home Heating

Energy that is received on the roof of a house is more than enough to supply the heating needs of the home. The energy reaching the earth from the sun ranges from 600 to 2000 BTUs per square foot per day (averaged over a year). It is a function of the latitude of the place. The amount of solar radiation reaching the earth is called the insolation. This is a short for incident solar radiation per day.

The earth revolves around the sun with its axis tilted toward the plane of rotation.

- In June, the North Pole is tilted toward the sun and the solar rays are incident perpendicularly. Therefore, the sun appears to be at a higher angle.

- In December, the North Pole is tilted away from the sun and therefore days are shorter and the solar rays are incident more obliquely, with lower energy flux (winter).

The sun also changes in position and angle from the earth during various times of the year.

Instructions: Press play to observe the movement of the sun as a function of the seasons.

Active Solar Heating Systems

Solar heating systems are classified as “active” or “passive” solar heating systems, or a combination of both. We will first look at active systems.

Active solar heating systems are comprised of collectors, a distribution system, and a storage device.

Instructions: Click on the hot spots in the image below to find out more about the main components of an active solar heating system.

Active solar heating systems operate as follows:

- Flat plate collectors are usually placed on the roof or ground in the sunlight. The top or sunny side has a glass or plastic cover to let the solar energy in. The inside space is a black (absorbing) material to maximize the absorption of the solar energy.

- Cold water is drawn from the storage tank by pump #1 and is pumped through the flat plate collector mounted on the roof of the house.

- The water absorbs the solar energy and is returned back to the tank.

- Warm water from the tank is pumped by pump #2 though the heating coil.

- The fan blows air (from the room) over the heated coil, and the heated air then passes into the room and heats the room.

- Cold air sinks to the bottom and is recirculated over the heating coil.

Note: The standby electric coil is automatically turned on and provides the heat when the water temperature to the heating coil drops because of consecutive cloudy days.

Instruction : Click the “play” button to observe the operation of an Active Solar Heating System:

Collector’s Efficiency is the ratio of solar radiation [6] that is captured and transferred to the collector or heat transfer fluid.

The efficiency of a collector can be expressed as:

Typical collector efficiencies range from 50–70 percent.

Passive Solar Heating Systems

Passive systems do not use mechanical devices such as fans, blowers, or pumps to distribute solar heat from a collector. Instead, they take advantage of natural heat flow to distribute warmth. An example of a passive system for space heating is a sunspace or solar greenhouse.

Passive systems also make use of materials with large heat capacities (stone, water, or concrete) to store and deliver heat. These are called thermal masses.

Instructions: Click on the hot spots in the image below to see the essential elements of a passive solar system.

Passive systems can be categorized into three types:

- Direct Gain - Allows the solar energy to come in through the south-facing window panes.

- Indirect Gain - Allows the solar radiation to heat a wall and then the energy is slowly delivered into the interior of the house. Openings in the wall (called a Trombe Wall), as shown in the figure below, promote convective currents:

- Cold room air enters the space between the glass panel and the wall through the bottom opening.

- As this cold air gets heated, it rises to the top and comes in through the top opening.

- Greenhouse Addition - An attached sunspace and/or solar greenhouse heated by the solar energy - where some of the energy is used to grow the plants and some of it is used to heat the interior of the house.

These systems are shown below.

Costs and Benefits

It is usually most economical to design an active system to provide 40 to 80 percent of the home’s heating needs. Systems providing less than 40 percent of the heat needed for a home are rarely cost-effective, except when using solar air heater collectors that heat one or two rooms and require no heat storage.

A well-designed and insulated home that incorporates passive solar heating techniques will require a smaller and less costly heating system of any type, and may need very little supplemental heat other than solar.

The cost of an active solar heating system will vary. A simple window air heater collector can be made for a few hundred dollars. Commercial systems range from $30 to $80 per square foot of collector area, installed. Usually, the larger the system, the less it costs per unit of collector area. Commercially available collectors come with warranties of 10 years or more, and should easily last decades longer.

Heating your home with an active solar energy system can significantly reduce your fuel bills in the winter. A solar heating system will also reduce the amount of air pollution and greenhouse gases.

Environmental Protection

Ways to Improve Energy Efficiency of Heating Systems

Instructions: Click on the hot spots in the image below to find out how you can improve the energy efficiency of a heating system.

Review and Extra Resources

Review Sheet Lesson 8 – Home Heating

- Home Heating Systems

- Most commonly used heating fuel

- Types of heating systems

- Operating principle of the various types of heating systems

- Advantages and Disadvantages of the various types of heating systems

- Heat pumps

- Operating principle

- Efficiency

- COP calculation when inside and outside temperatures are given. Remember to convert temperatures to K in these calculations.

- What happens when one temperature changes (either inside or outside) the COP?

- Geothermal heat pumps

- Operating principle

- Classification – Difference between open loop and closed loop, vertical and horizontal loops

- Benefits

- Passive and Active Solar Heating methods

- Ways to improve the energy efficiency of the heating systems

Test Yourself

The questions below are your chance to test and practice your understanding of the content covered in this lesson. In other words, you should be able to answer the following questions if you know the material that was just covered! If you have problems with any of the items, feel free to post your question on the unit message board so your classmates, and/or your instructor, can help you out!

- Compare and contrast the three conventional heating methods (forced air duct, hydronic floor, and baseboard heating systems).

- Describe any five methods (total) to reduce home heating/cooling costs, and explain how each step reduces the energy consumption.

- Explain the operation principle of a ground source heat pump. Explain the difference between an open-loop and a closed-loop GHP.

- What is the difference between active and passive heating systems?

- With a neat sketch, describe how an active solar heating system works.

- Describe any three passive heating methods.

- Explain how a geothermal heat pump works and why it is so efficient.

- Explain clearly how an air-to-air heat pump works. List the main components used in the heat pump.

Extra Resources

For more information on topics discussed in Lesson 8, see these selected references:

- Aubrecht, G.L. Energy. Englewood Cliffs, NJ: Prentice Hall, 1995.

- Christensen, J.W. Global Science: Energy Resources Environment. 4th ed. Dubuque, IA: Kendall/Hunt, 1996.

- Fay, J.A, and Golomb, D.S. Energy and the Environment. New York: Oxford University Press, 2002.

- Hinrichs, R.A. Energy. Philadelphia: Saunders College Publishers, 1992.

- Space Heating by Climate Zone [7]

- Forced Air Furnace [8]

- Bob Villa Home Improvement [9]

- HomeTips [10]

- Office of Energy Efficiency and Renewable energy [11]

- Orange and Rockland [12]

Lesson 8 Deliverables

Deliverable 1

You must complete a short quiz that covers the reading material in lesson 8. The Lesson 8 Quiz, can be found in the Lesson 8: Home Heating Systems module in Canvas. Please refer to the Calendar in Canvas for specific time frames and due dates.