Lesson 10: Windows

The links below provide an outline of the material for this lesson. Be sure to carefully read through the entire lesson before returning to Canvas to submit your assignments.

Introduction & Checklist

Welcome to Lesson 10!

Lesson 10 Objectives

Upon completing this lesson, you should be able to:

- explain how windows work;

- explain the mechanisms of heat loss through windows;

- list important factors in selecting windows;

- calculate pay-back period when replacing with energy-efficient windows.

Checklist for Lesson 10

Here is your "to do" list for this week.

| Step | Activity | Access / Directions |

|---|---|---|

| 1 | Read the online lesson | Lesson 10 - Windows |

| 2 | Review | Lesson 10 - Review and Extra Resources (supplemental materials that are optional...but informative!). |

| 3 | Take | Lesson 10 - Quiz (graded). The quiz is available in Canvas. |

See the Calendar tab in Canvas for due dates/times.

Questions?

If you have any questions, please post them to the General Course Questions forum in located in the Discussions tab in Canvas. I will check that discussion forum daily to respond. While you are visiting the discussion board, feel free to post your own responses to questions posted by others - this way, you might help a classmate!

Windows and Heat Loss

Windows typically occupy about 15 to 20 percent of the surface area of the walls. Windows not only add aesthetic looks and often a very important aspect of a home, but also a very significant component of home heating and cooling costs. Windows lose more heat per square foot of area in winter and gain more heat in summer than any other surface in the home.

We already discussed in Lesson 5 that simple glass (1/8th inch) has a very low R-value (0.03). So even if the walls are well insulated to an R-value of about 13 to 19 and the windows have poor R-value, most of the heat escapes through the windows and the purpose of having a well insulated wall is lost.

It is estimated that in 1990 alone, the energy used to offset unwanted heat losses and gains through windows in residential and commercial buildings cost the United States \$20 billion (one-fourth of all the energy used for space heating and cooling). However, when properly selected and installed, windows can help minimize a home's heating, cooling, and lighting costs.

Heat Loss Through Windows

Instructions: Click the play button to see how heat loss occurs through a window. (21 seconds)

Although energy is spent heating the air in the room, windows can make the temperatures uncomfortable. However, by making the windows efficient, a significant amount of the energy and money can be saved.

Here is a graph that compares heating costs for different types of windows. The figures are based on a typical home in Boston, MA, a relatively heating intensive place.

Similarly, poor windows allow the solar energy to penetrate through the windows and heat the space. The incoming solar radiation consists of infrared (IR), ultraviolet (UV), and visible waves.

The IR radiation, which is also called heat radiation, heats the space excessively and adds to the air conditioning in the summer time. Therefore, energy efficient windows are critical in summer time or even in places where the cooling requirement is high.

Instructions: Click the “play” button to observe the effects of solar energy on windows. (13 seconds)

Here is a graph that compares cooling costs for different types of windows. The figures are based on a typical home in Phoenix, AZ.

Factors in Window Selection, page 1

The National Fenestration Rating Council (NFRC) developed an energy performance label that helps to determine how well a window performs the functions of helping to cool a building in the summer, warm a building in the winter, keep out wind, and resist condensation.

By using the information contained on the label, builders and consumers can reliably compare one product with another, and make informed decisions about the windows, doors, and skylights they buy. NFRC adopted a new energy performance label in 1998. It lists the manufacturer, describes the product, provides a source for additional information, and includes ratings for one or more energy performance characteristics.

NFRC rates all products in two standard sizes so that consumers and others can be sure they are comparing products of the same size. There are three factors that will be listed on the label with some additional information. These factors are U factor, Visible Transmittance (VT) and Solar Heat Gain Coefficient (SHGC).

U-Factor or Value

U-factor measures how well a product prevents heat from escaping. The rate of heat loss is indicated in terms of the U-factor (U-value) of a window assembly.

- U-Factor ratings generally fall between 0.20 and 1.20.

- The ratings are based on an outdoor temperature of 0oF (-18oC) and an indoor temperature of 70oF (21oC)

- Most window manufacturers label their windows with a U-value (conductance of heat, Btu/h °F ft 2).

U-values are the reciprocals of R-values (h °F ft 2/Btu).

- The lower the U-value, the less heat is lost through the window.

- The lower the U-value, the greater a window's resistance to heat flow and the better its insulating value, which is indicated by the R-value.

Thus, the U-value is the inverse of the R-value or:

Some manufacturers rate thermal performance using R-Value. For example, an R-factor of 4.0

is the same as a U-Factor of 0.25.

The overall, "total," or "whole window" U-Factor of any window depends on the type of glazing, frame materials and size, glazing coatings, and type of gas (air, or inert argon or krypton) between the panes. Some typical U-, and R- Factor ranges for different window assemblies are shown in the table below:

| Window Assembly | U-Factor | R-Value |

|---|---|---|

| Single Glazed | 0.91–1.11 | 1.1–0.9 |

| Double Glazed | 0.43–0.57 | 2.3–1.7 |

| Triple Glazed | 0.15–0.33 | 6.7–3.3 |

Factors in Window Selection, page 2

Solar Heat Gain Coefficient

Solar Heat Gain Coefficient (SHGC) measures how well a window blocks heat from the sunlight.

- The SHGC is the fraction of incident solar radiation admitted through a window, both directly transmitted, and absorbed and subsequently released inward.

- SHGC is expressed as a number between 0 and 1.

- The lower a window's solar heat gain coefficient, the less solar heat it transmits.

Visible Transmittance

Visible Transmittance (VT) measures how much visible light comes through a window.

- The visible transmittance is an optical property that indicates the amount of visible light transmitted.

- VT is expressed as a number between 0 and 1.

- The higher the VT, the more light is transmitted.

The light-to-solar gain ratio(LSGR) provides a gauge of the relative efficiency of different glass types in transmitting daylight while blocking heat gains. It is determined by the ratio between VT and SHGC.

The higher the ratio number, the brighter the room is without adding excessive amounts of heat.

The table below lists typical SHGC, VT, and LSGR values for different types of glass according to:

- Total Window

- Center of Glass (in parentheses)

| Window and Glazing Types | SHGC (0-1 scale) |

VT (0-1 scale) |

LSGR ( SHGC:VT) |

|---|---|---|---|

| Single-glazed, clear | 0.79 (0.86) | 0.69 (0.90) | 0.87 (1.04) |

| Double-glazed, clear | 0.58 (0.76) | 0.57 (0.81) | 0.98 (1.07) |

| Double-glazed, bronze | 0.48 (0.62) | 0.43 (0.61) | 0.89 (0.98) |

| Double-glazed, spectrally selective | 0.31 (0.41) | 0.51 (0.72) | 1.65 (1.75) |

| Double-glazed, spectrally selective | 0.26 (0.32) | 0.31 (0.44) | 1.19 (1.38) |

| Triple-glazed, new low-e | 0.37 (0.49) | 0.48 (0.68) | 1.29 (1.39) |

The following two parameters are not required to be reported on NFRC label, but are optional.

Air Leakage

Air Leakage (AL) is indicated by an air leakage rating expressed as the equivalent cubic feet of air passing through a square foot of window area (cfm/sq ft). Heat loss and gain occur by infiltration through cracks in the window assembly, by convection. The lower the AL, the less air will pass through cracks in the window assembly.

Condensation Resistance

Condensation Resistance (CR) measures the ability of a product to resist the formation of condensation on the interior surface of that product. The higher the CR rating, the better that product is at resisting condensation formation. While this rating cannot predict condensation, it can provide a credible method of comparing the potential of various products for condensation formation. CR is expressed as a number between 0 and 100.

Instructions: For each of the following, calculate the R-value and LSG. (Round your answers up to two decimal places.) After you enter your answers in the boxes below, check your work by clicking on the “check” buttons below.

Click here to open a text description of the Calculating R-Value and LSGR activity

Shading Devices

Before innovations in glass, films, and coatings in the past decade, a typical residential window with one or two layers of glazing allowed roughly 75 to 85 percent of the solar energy to enter a building, which has a negative impact on summertime comfort and cooling bills, especially in hot climates.

Instructions: Click on the hot spots in the image below to see the properties of a normal window.

External Window Shading

External window shading devices such as awnings, roof overhangs, shutters, and solar screens, and internal shading devices such as curtains and blinds, can control the entry of solar heat. Although external window shading devices are about 50 percent more effective than internal devices at blocking solar heat, they do have some disadvantages.

Instructions: Click on the hot spots in the image below to see the disadvantages of external window shading.

Internal Shading Devices

The table below shows the percentages of the radiant energy that different types of internal shading devices transmit, reflect, or absorb.

| Shade Type | Transmitted energy (percent) | Reflected energy (percent) | Absorbed energy (percent |

|---|---|---|---|

| Roller Shades | 25 percent | 15 - 80 percent | 20 - 65 percent |

| Vertical Blinds | 0 percent | 23 percent | 77 percent |

| Venetian Blinds | 5 percent | 40 - 60 percent | 35 - 55 percent |

Advances in Window Technologies, page 1

Research in the recent past led to the development of low-emissivity or "low-e," glass and films that control heat gain and loss, reduce glare, minimize fabric fading, provide privacy, and occasionally provide added security in wind, seismic, and other high-hazard zones. New construction and window replacement applications commonly use glazing with these coatings.

Some low-e coatings and solar control films reduce solar heat gain without impairing visible light transmission excessively. These include tinted glass and spectrally selective coatings, which transmit visible light while reflecting the infrared portion of sunlight.

Many spectrally selective coatings or glazings also have some low-e properties as well.

Types of Glazing

Modern window glazing falls into three categories:

- Chemically or physically altered glass

- Coated glass or films

- Multiple-layered assemblies with or without either of the first two items.

Chemically or Physically Altered Glass

Tinting – One of the oldest of all the modern window technologies. Under favorable conditions, tinting can reduce solar heat gain during the cooling season by 25 percent to 55 percent. Tinted glass is made by alteration of the chemical properties of the glass. Both glass and plastic laminate may be tinted.

The tints absorb a portion of the sunlight and solar heat before it can pass all the way through the window to the room. Tinted glazings reduce the latter by 25 to 55 percent. "Heat absorbing" tinted glass maximizes its absorption across some, or all, of the solar spectrum. Unfortunately, the absorbed energy often transfers by radiation and convection to the inside.

Coated glass or films

Spectrally Selective Coatings

Spectrally selective coatings or tints reduce infrared light (heat) transmission while allowing relatively more visible light to pass through (compared to bronze- or gray-tinted glass).

For buildings that use daylight for lighting, a spectrally selective window is a good choice. Spectrally selective glass also absorbs much of the ultraviolet (UV) portion of the solar spectrum.

In a multi-paned window, they function best as the outermost sheet of glazing. Thermal performance is increased when combined with a low-e coating. Spectrally selective coatings often have a light blue or green tint.

Low–e Coatings

Low-e and reflective coatings usually consist of a layer of metal a few molecules thick. The thickness and reflectivity of the metal layer (Low-E coating) and the location of the glass it is attached to directly affects the amount of solar heat gain in the room.

Most window manufacturers now use one or more layers of low-e coatings in their product lines. Any low-e coating is roughly equivalent to adding an additional pane of glass to a window.

Instructions: Click on the hot spots in the image below to see the properties of Low-E coating windows:

Low-e coatings reduce IR heat transfer by 5 to 10 times. The lower the emissivity value (a measure of the amount of heat transmission through the glazing or coating), the better the material reduces the heat transfer from the inside to the outside.

Most low-e coatings also slightly reduce the amount of visible light transmitted through the glazing relative to clear glass. The table below gives the emissivity values for different types of glass.

| Type of Coating | Emissivity |

|---|---|

| Clear glass. Uncoated | 0.84 |

| Glass with single hard coat low-e | 0.15 |

| Glass with single soft coat low-e | 0.10 |

There are three types of low-e coating available: Soft, hard coatings, and Heat Mirror.

- Soft coat is applied to the surface of a glass at lower temperatures. It's not durable enough to be exposed to the elements, so it's only used on the inner surfaces of windows which are not exposed to the elements.

- Hard coat is produced by fusing metallic oxide to the hot surface of glass during manufacture and is found primarily on storm windows and removable energy panels. Hard coat is applied on the glass surface at a high temperature. One layer is about 1/10,000 the diameter of a human hair. Hard coat is not quite as energy efficient as soft coat, but is tough enough to be used on surfaces exposed to the elements. Both types of low-e coatings (within insulated glazing assemblies) typically last for 10 to 50 years.

- Heat Mirror is a proprietary product that's applied to a thin polyester sheet suspended between the two panes of dual pane window. The coating reflects radiant heat while the sheet decreases heat loss by splitting the air space in two.

The only spectrally selective coatings now available are modified soft coat low-e coatings. The selective properties of the coatings are determined by modifying the coating's thickness and number of layers. A spectrally selective tinted glazing with a pyrolytic hard coat serves a similar purpose. These spectrally selective hard coats are currently under development.

Aftermarket Films - "Aftermarket" films are available for application on existing windows. They are relatively easy to apply on glazing up to 36 square inches. They are often applied to the glass with a water-soluble adhesive. To reduce the possibility of bubbles and wrinkles on large windows, have the film installed professionally. Most films should be applied to the inside surface of the glass since they can be damaged easily by weather.

If you plan to install the film yourself, be careful to select the appropriate film for your needs, and understand all directions before beginning. Plastic films generally last about 8 to 10 years before they start looking worn.

Advances in Window Technologies, page 2

Types of Glazing Continued: Multiple Layered Assemblies

The third type of modern window glazing is multiple-layered assemblies with or without either of the first two items.

Gas Fills

Filling the space with a less conductive, more viscous, or slow-moving gas minimizes the convection currents within the space, conduction through the gas is reduced, and the overall transfer of heat between the inside and outside is reduced.

Argon and Krypton gases with measurable improvement in thermal performance have been used. A mixture of krypton and argon gases is also used as a compromise between thermal performance and cost. The table below compares the two gasses.

| - | Argon | Krypton |

|---|---|---|

| Cost | Inexpensive | More expensive |

| Miscellaneous | Nontoxic, nonreactive, clear and odorless | - |

Xenon gas may also be used and provides R-20 per inch.

Layers of Glass and Air Spaces

Layers of Glass and Air Spaces may be either single-pane, double-pane, triple-pane or multi-pane.

- Standard single-pane glass has very little insulating value (approximately R-1). It provides only a thin barrier to the outside and can account for considerable heat loss and gain. Traditionally, the approach to improve a window's energy efficiency has been to increase the number of glass panes in the unit, because multiple layers of glass increase the window's ability to resist heat flow.

- Double-pane or triple-pane windows have insulating air-filled or gas-filled spaces between each pane. Each layer of glass and the air spaces resist heat flow. The width of the air spaces between the panes is important, because air spaces that are too wide (more than 5/8 inch) or too narrow (less than 1/2 inch) have lower R-values (i.e., they allow too much heat transfer).

- Advanced, multi-pane windows are now manufactured with inert gases (argon or krypton) in the spaces between the panes because these gases transfer less heat than does air. Multi-pane windows are considerably more expensive than single-pane windows and limit framing options because of their increased weight.

During the late 1980s, manufacturers combined the technology of multiple glazing, low-E coatings, and gas-filling to create "super windows." These windows are highly insulated, with R-values that can go as high as R-9.

Advances in Window Technologies, page 3

Frame and Spacer Materials

Window frames are available in a variety of materials including aluminum, wood, vinyl, and fiberglass. Frames may be primarily composed of one material, or they may be a combination of different materials such as wood clad with vinyl or aluminum-clad wood. Each frame material has its advantages and disadvantages, as shown in the table below.

| - | Advantages | Disadvantages | How to Improve |

|---|---|---|---|

| Aluminum | Ideal for strength and customized window design | Conduct heat and therefore lose heat faster and are prone to moisture condensation. | Anodizing or coating will prevent corrosion and electro-galvanic deterioration of aluminum frames; thermal resistance can be improved by placing continuous insulating plastic strips between the interior and exterior frame. |

| Wood | Have higher R-values, are not affected by temperature extremes, and do not generally promote moisture condensation. | Require considerable maintenance in the form of periodic painting or staining. If not properly protected, wood frames can swell, which leads to rot, warping, and sticking. | |

| Vinyl (typically polyvinyl chloride (PVC) | Available in a wide range of styles and shapes, have moderate to high R-values, are easily customized, are competitively priced, and require very low maintenance. | Do not possess the inherent strength of metal or wood. | Larger-sized windows are often strengthened with aluminum or steel reinforcing bars. |

| Fiberglass | Some of the highest R-values; excellent for insulating; will not warp, shrink, swell, rot, or corrode. | Relatively new and are not yet widely available. Unprotected fiberglass does not hold up to the weather and therefore is always painted. |

Spacers are used to separate multiple panes of glass within the windows. Although metal (usually aluminum) spacers are commonly installed to separate glass in multi-pane windows, they conduct heat.

During cold weather, the thermal resistance around the edge of a window is lower than that in the center; thus, heat can escape, and condensation can occur along the edges.

Problems with Spacers

The following have been done to alleviate the problems associated with spacers:

- One manufacturer has developed a multi-pane window using a 1/8-inch-wide (0.32 centimeters-wide) PVC foam separator placed along the edges of the frame. Like other multi-pane windows, these use metal spacers for support, but because the foam separator is secured on top of the spacer between the panes, heat loss and condensation are reduced.

- Several window manufacturers now sandwich foam separators, nylon spacers, and insulation materials such as polystyrene and rockwool between the glasses inside their windows.

- A new type of spacer product called warm-edge technology has evolved in the industry to overcome the thermal inefficiency of conventional aluminum spacers. Warm-edge refers to the type of spacer material used to separate the panes of glass (or glazing) in an insulated window unit. If the material conducts less heat or cold than a conventional aluminum spacer at the edge of the glass, it is said to be "warm-edge." Most of these newer spacers are less conductive and outperform pure aluminum. But still they all contain some kind of metal. And metal is highly conductive.

- Available in the market is a NO-metal Super Spacer, which uses no metal and is made up of 100 percent polymer structural foam. Therefore, it is believed to improve the R-Value of the whole window and reduce moisture condensation problems.

Selecting Main Parameters of Windows

General guidelines for selecting the main parameters of windows based on the climate are provided in the table below.

| - | Colder climate | Moderate Climate | Warm Climate |

|---|---|---|---|

| U-Factor | Less than 0.33 | 0.33 | 0.33 |

| Visual Transmittance | 50 percent | >50 percent | >60 percent |

| SHGC | 0.4-0.55 | >0.55 | <0.4 |

| UV-Protection | >75 percent | 75 percent | 75 percent |

| Edge Spacers | Super Spacers | Warm edge spacers | Warm edge spacers |

| Frame | Non-conductive | Non-conductive | Non-conductive |

| Air leakage | <0.3 cfm/sq.ft | <0.3 cfm/sq.ft | <0.3 cfm/sq.ft |

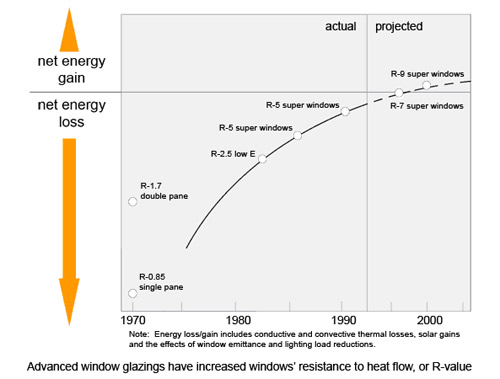

Improvement in Window Performance

The image below shows the improvement in window performance (R-value) with advanced window glazing. It can be seen from the figure that the super windows are losing less heat and are even making progress to gain heat instead of losing heat because of solar heat gains.

Smart Windows

Smart Windows operate very similarly to photochromatic sunglasses, which have lenses that darken automatically in response to bright light. Since windows let in heat as well as light, it would not be energy efficient to block out sunlight (heat) on a cold winter day. Therefore, smart windows have control switches that permit them to be manually turned on or off—so, instead of adjusting a shade or blind, one simply flicks the switch of the Smart Window.

Instructions: Click and drag the button in the image to see the amount of incoming light when the Smart Window is on and off.

Smart Windows use a new technology called Suspended Particle Devices (SPDs). They are small, light-absorbing microscopic particles or light valves. In Smart windows, millions of the SPDs are placed between two panes of glass that are coated with conductive material.

- When the Smart Windows are turned "on," electricity from the control switch travels through the conductive coating and causes the SPDs to line up and allow the passage of light.

- When the Smart Windows are turned "off," no electricity travels through the conductive coating, so the particles float freely between the glass, causing it to appear darkened or tinted.

A similar technology using electrochromics is also being developed to improve windows.

Instructions: Click the play button below to watch the Suspended Particle Devices animation and observe how the SPDs react. (16 seconds)

- Note: The animation has no sound and the text above describes how the suspended particles react in the animation when the electricity is "on" and "off."

Calculating Heat Loss of Windows

As you may recall from Chapter 7, heat loss is calculated using this formula:

Using this same formula, you can calculate the heat loss for windows.

Example 1

A house in State College, PA has 380 ft 2 of windows (R = 1.1), 2750 ft 2 of walls and 1920 ft 2 of roof (R = 30). The composite R-Value of the walls is 19. Calculate the heating requirement for the house for the heating season (HDD=6000). What is the percentage of heat that is lost through the windows?

Solution:

Heat loss in a heating season is given by

Heat Loss through windows =

Heat loss through walls =

Heat loss through roof =

Total heat loss = 79,803,560 BTUS

Percentage of heat loss through the windows =

Example 2

Windows in the house described in Example 1 are upgraded at a cost of \$1,550. The upgraded windows have an R-value of 4.0.

- What is the percent savings in the energy and the heating bill if the energy cost is 11.15/MMBTUs.

- What is the pay back period for this modification?

Solution:

a) New heat loss for the same window size with the new R-value is

Annual energy savings = 49.745 MMBTUs -13.680 MMBTUs = 36.06 MMBTUs

The percent savings is

The old heating bill would be

The new heating bill would be

The monetary savings = \$402.06 per year.

The Pay Back Period =

The table shows the cost effectiveness of replacing old windows with new and improved windows. The costs are calculated using a computer program called RESFEN developed by US Department of Energy.

| Performance | Base Model | Recommended Level | Best Available |

|---|---|---|---|

| Window Description | Double-paned, clear glass, aluminum frame | Double-paned, low-e coating, wood or vinyl frame | Triple-paned, tinted, two spectrally selective low-e coatings, krypton-filled, wood or vinyl frame |

| SHGCa | 0.61 | 0.55 | 0.20 |

| U-factor b | 0.87 | 0.40 | 0.15 |

| Annual Heating Energy Use | 547 therms | 429 therms | 426 therms |

| Annual Cooling Energy Use | 1,134 kWh | 1,103 kWh | 588 kWh |

| Annual Energy Cost | \$290 | \$240 | \$210 |

| Lifetime Energy Cost c |

\$4,700 | \$3,900 | \$3,400 |

| Lifetime Energy Cost Savings | - | \$800 | \$1,300 |

a SHGC, or Solar Heat Gain Coefficient, is a measure of the solar radiation admitted through a window. SHGC ranges between 0 and 1; the lower the number, the lower the transmission of solar heat. SHGC has replaced shading coefficient (SC) as the standard indicator of a window's shading ability. SHGC is approximately equal to the SC multiplied by 0.87.

b U-factor is a measure of the rate of heat flow through a window. The U-factor is the inverse of the R-value, or resistance, the common measure of insulation.

c Lifetime energy cost savings is the sum of the discounted value of annual energy cost savings, based on average usage and an assumed window life of 25 years. Future energy price trends and a discount rate of 3.4 percent are based on Federal guidelines (effective from April 2000 to March 2001). Assumed electricity price: \$0.06/kWh, the Federal average electricity price in the U.S. Assumed gas price: \$0.40/therm, the Federal average gas price in the U.S.

Cost-Effectiveness Assumptions: The model shown above is the result of a simulation using a residential windows modeling program called RESFEN [3]. Calculations are based on a prototype house: 1,540 sq. ft., two stories, a standard efficiency gas furnace and central air conditioner, and window area covering 15 percent of the exterior wall surface area.

Review and Extra Resources

Review Sheet Lesson 10 – Windows

- Windows and Heat Loss

- Solar radiation has infrared (IR), ultraviolet (UV), and visible waves

- Factors in window selection

- U factor

- Visible Transmittance (VT)

- Solar Heat Gain Coefficient (SHGC)

- Air Leakage (AL)

- Condensation Resistance (CR)

- R = 1 / U

- LSG = VT / SHGC

- Shading Devices

- Roller Shades

- Vertical Blinds

- Venetian Blinds

- Window Technologies

- Types of Glazing

- Chemically or Physically Altered Glass (tinting)

- Coated glass or films

- Spectrally Selective Coatings

- Low-e Coatings

- Soft Coat

- Hard Coat

- Heat Mirror

- After market Films

- Multiple-layered assemblies

- Gas Fills (argon, krypton)

- Layers of Glass and Air Spaces

- Single Pane

- Double Pane

- Multiple Pane

- Frame and Spacer Materials

- Types of Glazing

- Smart Windows

- Suspended Particle Devices (SPDs)

- Heat Loss = Area x HDD x 24 / R-value

Test Yourself

The questions below are your chance to test and practice your understanding of the content covered in this lesson. In other words, you should be able to answer the following questions if you know the material that was just covered! If you have problems with any of the items, feel free to post your question on the unit message board so your classmates, and/or your instructor, can help you out!

- What are the main factors that are important in selecting a window?

- Explain briefly what technological advances account for increase in performance of windows.

- What are gas filled windows, and how do they perform better than regular windows?

- Is it true that a person in Alaska requires high SHGC of windows?

- If thickness of the window is doubled, what will be the new percentage heat loss?

- What will be the heat loss from a window if it is vacuum between two window panes?

- A glazing material cost about $1/ ft2 which improves the insulation by 10%. What is the payback period of adding the glazing if originally window glass cost is $10/ft2 and heat loss from window is 1000 BTU/hr. Assume the cost of heating is $10/MMBTU.

- A house in State College, PA consists of the following: 12 single pane windows (each 6 ft by 3 ft with an R value of 1). Calculate the total number of BTUs lost for one season through these 12 windows. HDD for State College are 6,000.

- Heat loss through a window (R-2) is 10 MMBTU/year. Calculate the payback period if following filling material is used. Assume heating price to be $10/MMBTU

Calculate Heat Loss Example Gas fill Additional Cost Effective R Payback period (year) Argon \$20 7 Krypton \$45 12 Xenon \$75 20

Extra Resources

For more information on topics discussed in Lesson 10, see these selected references:

Lesson 10 Deliverables

Deliverable 1

You must complete a short quiz that covers the reading material in lesson 10. The Lesson 10 Quiz, can be found in the Lesson 10: Windows module in Canvas. Please refer to the Calendar in Canvas for specific time frames and due dates.