Lesson 10: Utility Scale Solar + Storage

Overview

Overview

This week, Lesson 10 continues the topic of energy storage – here we will try to identify the key issues related to the storage scale-up, when very large quantities of energy need to be stored for a relatively long period of time. In this lesson you will review the key metrics that help us compare different storage options and will apply those metrics in a storage sizing problem. This short, but useful exercise allows you to bring your understanding of battery parameters in a practical plane.

The discussion in this lesson is dedicated to the case study of PV+storage system operating in Hawaii – there are some good lessons to learn from the emergency situations on the Kauai Island demonstrating the ability of battery arrays to respond to blackouts.

Readings

Tesla's Hornsdale Power Reserve in Australia:

- Hornsdale Power Reserve [1]

- Hornsdale Power Reserve Overview [2]

- Tesla Beats Deadline, Switches on Gigantic Australian Battery Array [3]

- Tesla's Massive Powerpack Battery in Australia Cost $66 Million and Already Made up to ~$17 million [4]

AES Case Studies of Stationary Storage:

Angamos Storage Array:

Web article: Roselund, C., The Birth of the Solar+Storage Peaker [8], pv magazine, January 8, 2019

Journal article: Gramling, C., The Search for New Geologic Sources of Lithium could Power a Clean Future [9], Science News, Vol. 195, No. 9, May 11, 2019, p. 40.

USGS Report: Mineral Commodity Summaries: Lithium, 2019 [10]

Website: Check out this website for more information on Li mining [11] and extraction, methods, and major impacts in various regions of the World.

10.1 Purpose and Function of Utility Scale Storage Systems

Purpose and Function of Utility Scale Storage Systems

Energy storage technologies are expected to enable of electric grid modernization, addressing the current limitations of electricity infrastructure and increasing grid stability and resiliency. We can identify a number of critical functions that we expect the energy storage systems to perform.

- Integration of renewable energy into the electricity grid

The variability of solar and wind power makes it hard for electricity providers to plug them into the electricity grid. Grids constantly balance the supply and demand of electricity and thus benefit most from dispatchable sources of energy (so far fossil fuels that could be burned on demand provided that sort of convenience). Energy storage makes the solar and wind energy more dispatchable (available on-demand of grid operators) and hence more competitive with traditional fuel options.

- Addressing peak demand

Responding to peak demands requires the ability to generate power quickly. The traditional choice for peak power generation are natural gas turbines. The energy stored in the batteries is immediately available and can be used to meet peak demand. This helps use the renewable power for peak generation and avoid grid disruptions or blackouts.

- Time shifting

PV Solar panels generate power only during the daytime, with the peak at noon hours, while the peak energy demand is often located during evening hours, when the solar irradiation is low. So the solar power needs to be “time-shifted” to be available during the time of high demand, and this can be achieved by means of utility scale storage.

- Energy autonomy and independence

For communities living in areas without access to electricity grid, combined renewable energy plus storage systems may be the best option to provide for constant supply of electricity. This autonomous approach can be realized at both distributed (house / community) and utility (area / region) scales.

Probing Question

Can you think of other major purposes or functions provided by energy storage systems? What other services to industry and community can we expect from the storage technology development in the future?

Check out Table 10.1, which provides more detail on how storage systems serve the grid and help diversify the energy resources.

| Role | Time scale(s) | Description | Benefits to RE integration | Examples of EES technologies |

|---|---|---|---|---|

| Time shifting / Arbitrage / Load levelling | Hours to days | EES allows storage of off-peak energy and release during high-demand period | A solution to diurnal generation cycles that do not match load cycles | NaS batteries, CAES, PHS, RFB |

| Seasonal shifting | Months | EES stores energy for months at a tie, releasing it at times of the year when RE output is typically lower | Allows use of renewably-generated energy year-round reducing reliance on traditional generation in seasons with, e.g., low sunlight | Hydrogen, SNG |

| Load following / Ramping | Minutes to hours | EES follows hourly changes in demand throughout the day | May mitigate partial unpredictability in RE output during critical load times | Batteries, flywheels, PHS, CAES, RFB |

| Power quality and stability | < 1 second | Provision of reactive power to the grid to handle voltage spikes, sags and harmonics | Mitigate voltage instability and harmonics caused or exacerbated by uncontrollable variability of capital RE generation | LA batteries,NaS Batteries, flywheels, RFB |

| Operating reserves | ||||

| Frequency regulation | Seconds to minutes | A fast-response Increase or decrease In energy output to stabilize frequency | Mitigate uncontrollable moment-to-moment variability in RE generation output | Li-ion Batteries, NaS Batteries, Flywheels, PHS (with advanced variable speed control) |

| Spinning Reserves | ~10 Minutes | A fast-response increase or decrease in energy output to cover a contingency, e.g. generator failure | Mitigates partial unpredictability RE generation output, providing (or removing) energy win the RE resource does not perform as expected | PHS, flywheels, batteries |

| Supplemental reserves | Minutes to hours | A slower response resource that comes online to replace a spinning reserve | Provide a firm power in the event of an especially severe and long-lasting drop in RE output. Use for RE integration is expected to be infrequent and low-value | PHS |

| Efficient use of transmission network | Minutes to hours | EES can help grid operators defer transmission system upgrades through time-shifting and more efficient operating reserves | Reduced transportation costs, mitigate locational dependency challenges of RE generation | Li-ion |

| Isolated grid support | Seconds to hours | EES can assist in the integration of RE on small power grids, such as those in use on islands | Time-shifting and power quality applications to mitigate variability and unpredictability of RE generation | LA batteries |

| Emergency power supply / Black start | Minutes to hours | EES may be used to re-start the power system in the event of a catastrophic failure | No specific benefit accrues to RE integration, but storage resources may nonetheless provide black start capability to gird | LA batteries |

These purposes and applications require storage systems of diverse scale. The concept of scale has two dimensions: space and time. Space scale is related to the size and capacity of the storage, while timescale indicates how long the energy can be stored. Take a look at the figure below, which presents rough classification of storage systems in terms of size and time.

In this diagram, we see that such devices as capacitors store small amount of energy on the scale of seconds and minutes. At the same time, the systems shown in the right upper corner - pumped hydro storage, chemical storage - can store amounts of energy worth of gigawatt-hours over long periods of times (months to years). The same as with power generation technologies, storage system variety is important to satisfy various applications and demands and also to provide service storage in diverse natural and industrial settings.

The selection of the energy storage depends on many technical characteristics (besides scale), which would help us to understand why some technologies are preferred over others, and what trade-offs are involved in this selection. Let us look at some key storage characteristics next.

10.2 Key Metrics and Definitions for Energy Storage

Key Metrics and Definitions for Energy Storage

There are a few key technical parameters that are used to characterize a specific storage technology or system. Those characteristics will determine compatibility of the storage with a proposed application and will also have impact on its economic feasibility. Let us go through some definitions.

Storage Capacity

Capacity essentially means how much energy maximum you can store in the system. For example, if a battery is fully charged, how many watt-hours are put in there? If the water reservoir in the pumped hydro storage system is filled to capacity, how many watt-hours can be generated by releasing that water? Those amounts are determined by storage capacity.

Understandably, the capacity of any storage will increase with the system size. The more battery stacks are installed, the more electric energy can be put in for storage. The larger the water reservoir, the greater energy turnaround becomes possible. The system size should be matched with the load and specific application.

Storage capacity is typically measured in units of energy: kilowatt-hours (kWh), megawatt-hours (MWh), or megajoules (MJ). You will typically see capacities specified for a particular facility with storage or as total installed capacities within an area or a country.

| Portable scale | A portable battery pack with a storage capacity of 450 Wh... |

|---|---|

| Utility scale | One of the largest PV + storage projects in Texas – Upton 2 – has storage capacity of 42 MWh (which would be sufficient to power 1400 homes for 24 hours) |

| National scale | The total installed capacity of energy storage is the US is around 1000 MWh |

Sometimes you will see capacity of storage specified in units of power (watt and its multiples) and time (hours).

For example: 60 MW battery system with 4 hours of storage. What does it mean?

60 MW means that the system can generate electricity at the maximum power of 60 MW for 4 hours straight. That also means that the total amount of energy stored in the system is:

60 MW x 4 hours = 240 MWh

But it can also provide less power if needed. For example, if the load only requires 20 MW, the system can supply it for 12 hours. The total amount of stored energy is the same, but it is used more slowly:

20 MW x 12 hours = 240 MWh

So power and time ratings give us a little bit more information: we not only know how much energy is stored, but can also define at what maximum rate this energy can be potentially used.

Check Your Understanding Questions 1 & 2 (Multiple Choice)

Energy density

Energy density is often used to compare different energy storage technologies. This parameter relates the storage capacity to the size or the mass of the system, essentially showing how much energy (Wh) can be stored per unit cell, unit mass (kg), or unit volume (liter) of the material or device.

For example, energy densities for different types of batteries are listed in the table below [IES, 2011]:

| Battery type | Energy Density, Wh/liter |

|---|---|

| Lead-Acid battery | 50-80 |

| Li-ion battery | 200-400 |

| NiCd (nickel cadmium) battery | 15-80 |

| NiMH (nickel metal hydride) battery | 80-200 |

| NaS (sodium sulfur) battery | 150-300 |

| NaNiCl2 (sodium-nickel-chloride) battery | 150-200 |

| Zinc air battery | 130-200 |

| Vanadium redox flow battery | 20-70 |

| Hybrid flow battery | 65 |

Of course, we are interested to store as much energy as possible while using as small and light device as possible for this purpose. From the table above we can conclude, for example, that a fully charged Lead-Acid battery will run out of charge much sooner than a fully charged Li-ion battery of the same mass/size.

Energy density is related to capacity and determines the duration of power generation. Also materials with higher energy density help make the power block more compact, which is useful in portable electronics and vehicle applications.

Just for comparison, the energy density of the pumped hydro storage is 0.2—2 Wh/kg, which is rather low and requires significant masses of water and large reservoir size to deliver utility scale power.

Check Your Understanding Question 3 (Multiple Choice)

Power density

Power density (measured in W/kg or W/liter) indicates how quickly a particular storage system can release power. Storage devices with higher power density can power bigger loads and appliances without going oversize. Imagine an electric vehicle accelerating from 0 to 60 MPH – which takes a lot of power. If you look at the table below, you will see why Li-ion battery remains the technology of choice for powering electric vehicles, even though some other battery types exhibit similar energy densities.

| Battery type | Energy Density, Wh/liter | Power Density, W/liter |

|---|---|---|

| Lead-Acid battery | 50-80 | 90-700 |

| Li-ion battery | 200-400 | 1300-10000 |

| NiCd (nickel cadmium) battery | 15-80 | 75-700 |

| NiMH (nickel metal hydride) battery | 80-200 | 500-3000 |

| NaS (sodium sulfur) battery | 150-300 | 120-160 |

| NaNiCl2 (sodium-nickel-chloride) battery | 150-200 | 250-270 |

| Zinc air battery | 130-200 | 50-100 |

| Vanadium redox flow battery | 20-70 | .05-2 |

| Hybrid flow battery | 65 | 1-25 |

The technologies located in the lower left corner of the diagram (low energy density and low power density) take significant amount of space and material to enable the storage conversion and are mostly suitable for very large scale projects. Systems such as PHS and CAES also rely on the availability of specific landscape and geological features to accommodate the storage reservoirs.

The technologies located in the upper right corner of the diagram are most coveted for portable and efficient power supply, such as electric vehicles. These compact systems can carry a significant amount of energy and release it quickly on demand.

The technologies in the upper left corner are special devices that can be used in quick response electronics. These systems store small amounts of energy (and therefore charging can be fast), but are able to provide high power by releasing energy within short period of time.

Finally, the technologies in the lower right corner are characterized by slow charge and discharge, but the advantage is the total high amount of energy they are able to store, providing longer duration of energy supply.

Check Your Understanding Questions 4 & 5 (Multiple Choice)

Storage efficiency

The main function of any storage device is to uptake and release power on demand. In case of a battery, for example, it would be electrochemical charge/discharge cycle; in case of pumped hydro storage, this process involves pumping water into the elevated reservoir and later releasing the flow through the turbine. Both charge and discharge processes include one or more energy conversions (Figure 10.3). In the figure, each arrow indicates the energy conversion from one form to another.

Regardless the number of transformations, the energy comes to its initial electric form, which is finally ready to be dispatched into the grid. This is the charge-discharge cycle, the "round trip".

In each conversion, energy is partially lost from the cycle and dissipated into the surroundings, and the efficiency of conversion at every step accounts for those losses.

Efficiencies of all energy conversion steps in this cycle are combined in the metric called round-trip efficiency, which essentially indicates the percentage of energy delivered by the storage system compared to the energy initially supplied to the storage system. The obvious goal is to minimize the conversion losses and thus maximize the overall storage efficiency.

Here are some round-trip efficiencies of various energy storage systems:

| Storage system | Round-trip efficiency, % |

|---|---|

| Lead-Acid battery | 75-90 |

| Li-ion battery | 85-98 |

| Pumped hydro storage | 70-80 |

| Compressed air energy storage | 41-75 |

| Flywheel | 80-90 |

| Hydrogen | 34-44 |

| Double layer capacitors | 85-98 |

| Vanadium redox flow battery | 60-75 |

These numbers mean the following. For example, out of 1 MWh of energy spent to pump water up to the hydro storage, only 0.7-0.8 MWh will be available to use after the water is released to run the turbine and generator to produce electric power. The other 0.2-0.3 MWh of energy will be converted into non-useful forms of energy and “lost” from the cycle. Some of the energy losses occur in the auxiliary devices used in the energy storage process, very often in the form of waste heat. Furthermore, energy losses may be linked to the mechanical or material losses: for example, leaks and evaporation of water from pumped storage, air leaks in CAES, chemical degradation and incomplete reactions in batteries.

Check Your Understanding Questions 6 & 7 (Multiple Choice)

10.3 Implementation of Utility Scale Storage - Battery Arrays

Implementation of Utility Scale Storage - Battery Arrays

The large-scale energy storage (also called grid energy storage) is a stand-alone or hybrid system that allows storing large amounts of electrical energy within an electrical power grid. Until recently, the dominant form of grid-scale energy storage has been pumped hydroelectricity, which accounts for over 95% of global installed storage capacity. Pumped hydro storage is rather old technology and has been around since the early 20th century, however it did not prove to be economically profitable or highly efficient. Other challenge you face in pumped hydro is the need of a certain kind of geological terrain to accommodate the proper size reservoir and availability of a large amount of water. We can add to that the environmental concerns and possible human impacts that are typically associated with the large hydro plants. It appears to be really hard to adopt this version of storage quickly in the newly constructed energy facilities.

Currently, there is a pressing need for new generation storage devices, that would be efficient, cheap, and possibly modular in order to facilitate their allocation at any location with any required capacity. This niche is currently being filled by the battery array systems. Battery arrays are often stand-alone facilities, strategically located to support regional grid stability.

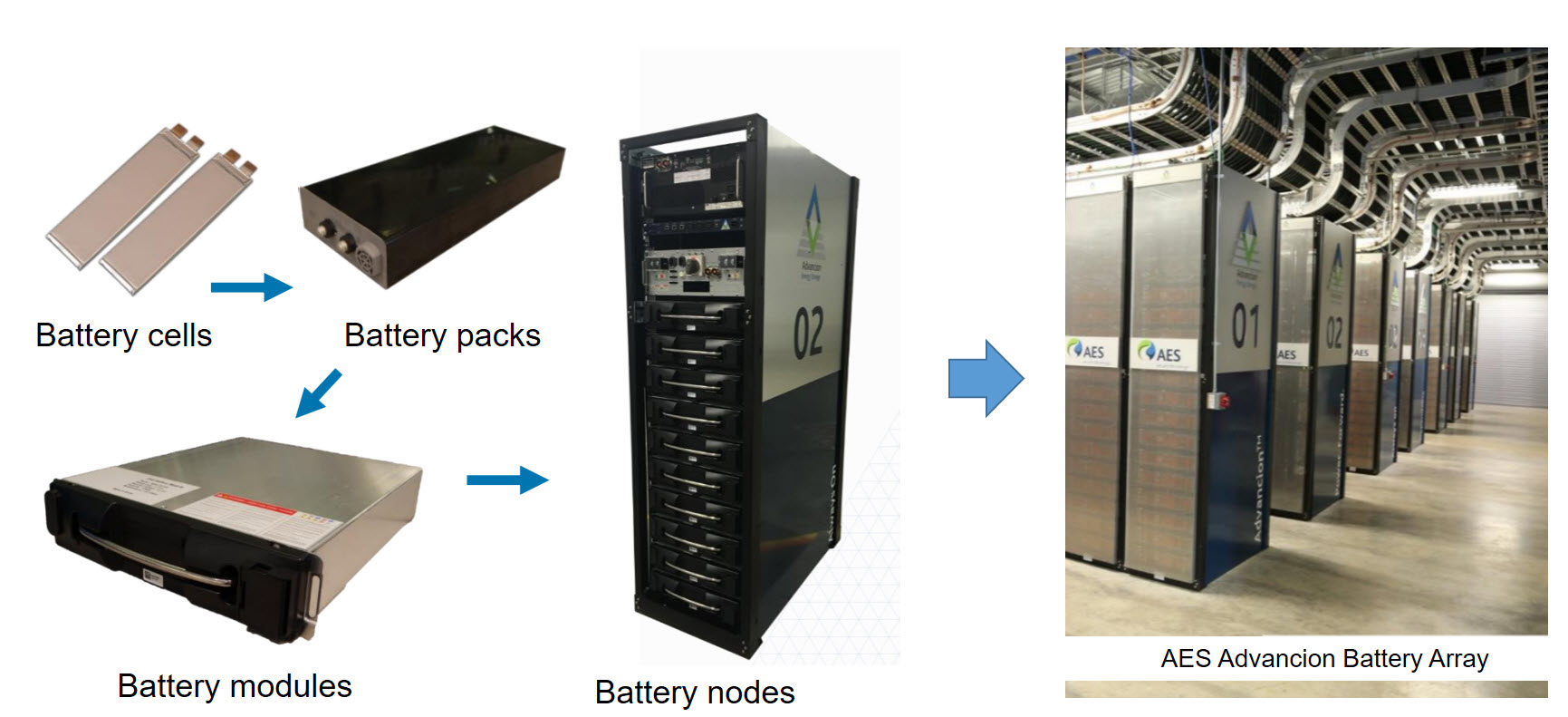

To be clear, the large battery energy storage systems (BESS) are not huge batteries as a matter of fact. Battery arrays are modulirized systems, in which individual battery cells (for example, Li-ion batteries) are stacked in series into higher voltage units. The same as solar cells are combined in panels, and pannels are organized in arrays, scaling-up battery systems follows the same principles of series and parallel connections in order to achieve the required power and capacity.

Some major companies that pursuing development and installation of large battery arrays are AES and Tesla. Follow the links below to learn about some case studies of battery array implementation:

- Tesla's Hornsdale Power Reserve in Australia:

- AES Case Studies of Stationary Storage:

- Angamos Storage Array

One of the advantages we can see with battery solutions for grid storage is flexibility. For one, they can act as a reliable backup source. In the event of a power outage, battery systems can be turned on quickly to compensate. Data shown in the presentation on Chile grid system (second link for Angamos Storage Array) demonstrate very quick response of the arrays to the power outage and successful grid balancing.

In Australia, Hornsdale Power Reserve (built byTesla) helped restore power to the country’s grid in a fraction of a second after an unexpected failure at a power plant.

"the Hornsdale Power Reserve has smoothed out at least two major energy outages, responding even more quickly than the coal-fired backups that were supposed to provide emergency power.

Tesla's battery last week kicked in just 0.14 seconds after one of Australia's biggest plants, the Loy Yang facility in the neighboring state of Victoria, suffered a sudden, unexplained drop in output, according to the International Business Times. And the week before that, another failure at Loy Yang prompted the Hornsdale battery to respond in as little as four seconds — or less, according to some estimates — beating other plants to the punch. State officials have called the response time “a record,” according to local media." (Washington Post, 2017 [12])

This table provides a list of other operating or commissioned projects, also including those based on other battery types (in addition to Li-ion):

| Project | Battery type | Location | Storage Capacity | Status/Date |

|---|---|---|---|---|

| Kingfisher Project | Lithium-ion | Roxby Downs, South Australia, Australia | 102 MW | Announced Dec 01, 2017 |

| AES Alamitos Energy Storage Array | Lithium-ion | Long Beach, CA, US | 100 MW | Contracted |

| Germany Residential Energy Storage Systems - 34,000 PV Battery Storage Systems@2 kW | Lithium-ion | Multiple, Multiple, Germany | 68 MW | Operational/Jan 31, 2016 |

| Kyushu Electric - Buzen Substation - Mitsubishi Electric/NGK Insulators | Sodium-sulfur | Buzen, Fukuoka Prefecture, Japan | 50 MW | Operational/Mar 03, 2016 |

| Gyeongsan Substation ESS - 48 MW ESS - KEPCO/Woojin/LG Chem | Lithium-ion | Gyeongsan-si, Gyeongsangbuk-do, Korea, South | 48 MW | Operational/Jul 01, 2016 |

| Nishi-Sendai Substation - Tohoku Electric/ Toshiba | Lithium-ion | Sendai, Miyagi Prefecture, Japan | 40 MW | Operational/Feb 20, 2015 |

| Minami-Soma Substation - Tohuka Electric/Toshiba | Lithium-ion | Minamisoma, Fukushima Prefecture, Japan | 40 MW | Operational/Feb 26, 2016 |

| 40 MW - AES/National Grid Corp. of the Philippines (Kabankalan) | Lithium-ion | Kabankalan, Negros, Occidental, Philippines | 40 MW | Operational |

| Notrees Battery Storage Project - Duke Energy | Advanced lead-acid | Goldsmith, TX, US | 36 MW | Operational/Jan 01, 2013 |

| Non-Gong Substation ESS - 36 MW ESS - KEPCO/Kokam | Lithium nickel manganese cobalt | Non-Gong Substation, N/A, Korea, South | 36 MW | Contracted |

| Rokkasho Village Wind Farm - Futamata Wind Development | Sodium-sulfur | Rokkasho, Aomori, Japan | 34 MW | Operational/May 01, 2008 |

| AES Laurel Mountain | Lithium-ion | Elkins, WV, US | 32 MW | Operational/Oct 01, 2011 |

| Beech Ridge Wind Storage | Lithium iron phosphate | Rupert, WV, US | 31.5 MW | Operational/Nov 04, 2015 |

| Grand Ridge Energy Storage | Lithium iron phosphate | Marseilles, IL, US | 31.5 MW | Operational/May 14, 2015 |

| Japan-Egypt-Hurghada | Lithium-ion | HurGhada, Red Sea Governorate, Egypt | 30 MW |

Announced |

| SDG&E Escondido Substation - AES | Lithium-ion | Escondido, CA, US | 30 MW | Contracted/Jan 31, 2017 |

| 30 MW SK Innovation BESS | Lithium-ion | Magdeberg, Saxony-Anhalt, Germany | 30 MW | Announced |

| Golden Hills - NextEra Energy | Lithium-ion | Livermore, CA, US | 30 MW | Contracted |

| Imperial Irrigation District BESS - GE | Lithium-ion | El Centro, CA, US | 30 MW | Under Construction/Oct 01, 2016 |

Source: Zhang, Wei, Cao, Lin. Energy storage system: Current studies on batteries and power condition system. [13] Renewable and Sustainable Energy Reviews. 2018 Feb; 82 (3): 3091-3106.

Batteries can also store extra energy. If there's excess power during peak wind or solar production, a battery can store up all that energy for future use. The Hornsdale plant is able to provide full power to 30,000 home, although for a relatively short period of time. In case of long outages, it still needs to be supported by traditional power generation facilities. In this way, battery essentially serves as an end user of power as well as a power plant.

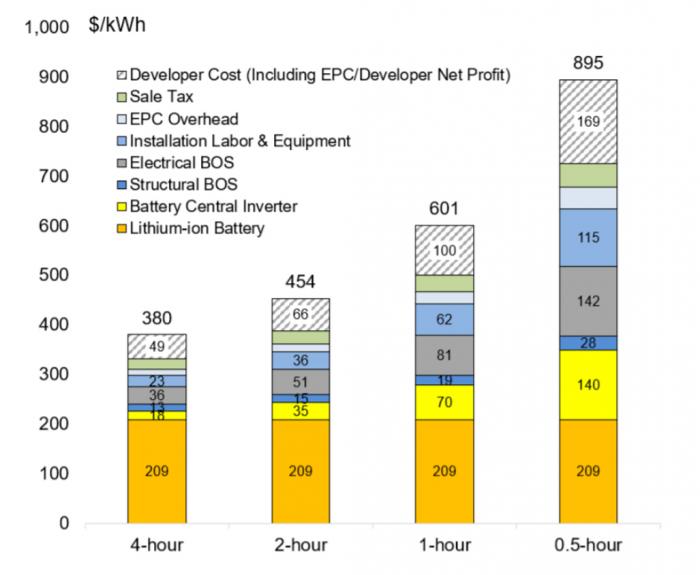

According to National Renewable Energy Laboratory (NREL Report, 2018 [14]), the cost of the stand-alone utility scale Li-ion battery storage system breaks down as follows:

Interesting to note that while the battery cost per unit energy remains the same (with battery system being modular), the costs related to the balance of system, installation, and service decline with the storage duration.

PV + Storage Systems

Co-locating the PV and storage systems has multiple benefits. Co-location results in cost savings by reducing costs related to site preparation, land acquisition, permitting, interconnection, installation labor, hardware (via sharing of hardware such as switchgears, transformers, and controls), overhead, and profit. The cost of the co-located, DC-coupled system is 8% lower than the cost of the system with PV and storage sited separately, and the cost of the co-located, AC-coupled system is 7% lower. (NREL Report, 2018 [14])

DC-coupling or AC-coupling of the energy source with storage can be used in different scenarios. DC-coupling is less expensive due to fewer conversions - 1% lower total cost than AC-coupling, which is the net result of cost differences between DC-coupling and AC-coupling in the categories of solar inverter, structural balance of system (BOS), electrical BOS, labor, EPC (engineering, procurement, and construction) and developer overhead, sales tax, contingency, and profit.

“According to NREL, there’s only one utility-scale PV system in the United States connected to storage, and it is Lawa'i project in Kauai, Hawaii. There are more systems that have storage co-located with a solar array, but those batteries can be charged by other sources of power on the grid. According to GTM Research’s “U.S. Energy Storage Monitor 2017 Year in Review,” more than 5,500 energy storage systems are installed in the U.S., in the residential and commercial sectors with over 95% connected to PV in the residential sector at the end of 2017, which amounts to about 4,700 systems. By the end of 2018, GTM estimates that solar-plus-storage will have accounted for about 4% of distributed PV and could reach 27% by 2023.” (Energy.gov, 2019 [15])

Based on this assessment, it looks like distributed PV market is somewhat ahead of the utility solar when it comes to hybrid PV+storage systems. It may change quickly. Look at the South Korea’s example:

“South Korea represents a story of how government planning can drive massive energy storage market growth, with a new policy to allow storage-backed wind and solar projects to earn renewable energy certificates worth five times their capacity value driving a massive boom in 2018. From less than 10 megawatt-hours deployed in 2017, South Korea’s utility-scale and commercial-industrial behind-the-meter deployments boomed to 1,100 megawatt-hours in 2018, with nearly $400 million in energy storage investments and a pipeline of projects that’s already overshot its goal of 800 megawatt-hours by 2020.” (JTM, 2019 [16])

But let us take a closer look at the Lawa'i Solar and Energy Storage plant on Kauai (HI), and try to find out what conditions made commission of this project a success.

Reading Assignment

Web article: Roselund, C., The Birth of the Solar+Storage Peaker [8], pv magazine, January 8, 2019.

This article gives you some basic information on the setting and parameters of the plant. But let us not stop there. The project was commissioned in the beginning of 2019. I ask you to research some more information on its current status and share your findings on the class discussion thread.

10.4 Resource Constraints and Environmental Considerations

Resource Constraints and Environmental Considerations

With energy storage industry changing fast, technology maturing, costs dropping, we can envision major shifts in both portable and stationary power markets. Cars and trucks will be powered by lithium-ion batteries rather than fossil fuel based internal combustion engines. Rechargeable lithium-ion batteries are also becoming crucial components of the new generation power grid to store increasing amounts of energy produced by solar and wind farms. This major technological scale-up will rely on the supply of new critical minerals and materials, such as lithium (Li), the lightest metal in the periodic table.

When thinking about this new future for our transportation and power industry, a few questions pop in our minds:

Where are we going to get all that lithium? (We are talking possibly 4-5 times topping the current market, perhaps more!) Is there enough of it on Earth? We are running out of oil, so would running out of lithium would get us in a similar trouble? How would prices for lithium affect international energy market and national economies of countries with higher or lower natural resource of this metal?

Companies such as Tesla, for example, already began a quest for control over lithium deposits across the globe, including countries in South America, Africa, and Australia.

Finally, mining and extraction of lithium at the accelerated rates will inevitably lead to serious environmental impacts on local and regional ecosystems (like any mining does), so how do these activities need to be regulated to keep this technology from becoming another global threat to biodiversity and human health?

To clarify some of these concerns, we are going to take a quick dive into the lithium lifecycle and learn about the key geological sources of its stock.

Reading Assignment

Web article: Gramling, C., The Search for New Geologic Sources of Lithium could Power a Clean Future [9], Science News, Vol. 195, No. 9, May 11, 2019, p. 40.

Mineral Spodumene is considered one of the key lithium ores and has been mined widely for multiple markets and applications.

Prospecting for lithium and estimates of natural reserves have been done by U.S. Geological Survey at different years, and numbers keep changing due to discovering new deposits and, on the other hand, due to increasing demand for lithium from the energy storage and vehicle industry. For example in 2015, USGS estimated that world has lithium reserves for 365 years based on the global average production rate of 37,000 tons per year. Since then production has been doubled at least and the estimate shifted.

This is relatively recent (February 2019) USGS report, which provides some statistics on currently estimated reserves and production.

Reading Assignment

USGS Report: Mineral Commodity Summaries: Lithium, 2019 [10]

This information can be the starting point for assessing the available reserves for Li-ion battery manufacturing and forecasting Li markets.

Countries that contain the largest lithium reserves include Argentina, Chile, Australia, and China. Among them, Australia is currently the leader in mining and production. You can make your own calculations based on the data provided and compare to some other online reports (but I am sure this information is not set in stone).

Next, answer a few self-check questions based on the above readings.

Check Your Understanding Question 8 (Multiple Choice)

Check Your Understanding Question 9 (Essay)

What is currently the most economically viable source of naturally available lithium at the moment due to the cheapest method of extraction?

Check Your Understanding Question 10 (Multiple Choice)

On the other side of the equation, we also need to understand the options for lithium disposal and recycling in the end of the battery lifetime.

Environmental Risks

Production and disposal of Li-ion batteries are associated with an array of environmental and health impacts, which include soil and water pollution due to open-pit Li mining, bio-toxicity, aquatic ecotoxicity (impact on fish), release of carcinogenic substances, high water and energy use. These impacts are not only associated with Li metal itself, but also with chemicals used to extract it from rocks or brines.

Supplemental Reading:

Website: Check out this website for more information on Li mining [20] and extraction, methods, and major impacts in various regions of the World.

Recycling of components and materials contained in Li-ion batteries becomes of paramount importance to mitigate two major issues: (1) resource depletion and (2) environmental pollution. Effective recycling programs would help reduce the need for opening new Li mines and offset the rate of lithium resource exhaustion at the national and global scales. Recycling routes would also help divert the battery products from landfills and thus avoid risks associated with chemical dispersion in soils, streams, and aquifers.

That said, the Li-ion battery recycling industry is really at its infancy still:

- Currently recycling of EV batteries consists of storage, landfill, and/or pyrometallurgical processes (burning in smelters).

- China - Legislated that all EV manufacturers and importers come up with a feasible recycling program.

- European Union - Has set a timeline for battery manufactures and importers to recycle spent lithium ion batteries.

- Canada - Has three provinces (British Columbia, Manitoba and Quebec) with mandatory recycling programs.

- USA - There is no Federal Regulations for battery recycling, some States do have.

(Source: Seeking Alfa, 2018 [21])

For the next discussion assignment, we will try to search for signs of new business developments and regulations inside and outside of the U.S. related to Li-ion battery recycling and see how things have improved over the recent couple of years.

Summary and Activities

Summary and Activities

This lesson overviewed the main trends in the development of the large-scale energy storage systems. These systems are considered to be pivotal enabling technologies for greater penetration of renewables into the power grid. Cost, size, and ability to quickly install storage at any location on demand are key factors that will ensure the dispatchability of the new energy resources. Choosing the proper storage technology and sizing the system for a project can be a tricky balancing act between the ability to meet power requirements over a certain period of time and investment cost. In this lesson, you had a chance to study several successful operating solar+storage projects that provide us with a realistic picture of benefits as well as challenges of utility scale storage implementation.

Please go through the following activities to complete this lesson.

| Type | Description/Instructions | Deadline |

|---|---|---|

| Readings | Complete all necessary reading assigned in this lesson. | |

| Yellowdig Discussion |

Join the Yellowdig community for the conversation about this lesson material. Check Module 10 in Canvas for suggested topics. |

the point-earning period for this week runs from Saturday to next Friday. |

| Activity |

PV + BESS Sizing Consider the following hypothetical scenario: Penn State’s main campus (University Park) aims to cover 25% of its electricity needs by solar energy. For that purpose, a utility scale PV + battery array system is to be deployed. The system should be able to provide 25% power off-grid if necessary. The PV plant will be feeding the load during the day and will also charge the BESS storage, which will be used to supply power during the night hours. Your goals will be (1) to determine the nameplate capacity for the PV installation and capacity of the BESS storage to meet the generation target, and (2) research vendors for BESS storage and suggest some options for storage units to deploy. Please see more specific instructions for this assignment in Module 10 in Canvas |

Wednesday night |