Module 1: Introduction to the Mining Industry

Module 1 Overview

Learning Outcomes

At the successful completion of this module, you should be able to:

- describe the importance of mining in terms the number of commodities mined, the number of mines, and the economic impact of mining;

- cite examples (at least 12) of nonfuel mineral commodities and the commercial use of these commodities;

- use the USGS Mineral Commodities Summary to obtain data on the commodities;

- describe, in general terms, the makeup of coal, the more important constituents or properties that affect its market value, and why those constituents or properties are of interest;

- define the rank of a coal and the four ranks of coal; and explain the chart commonly used to illustrate the classification of coals by rank;

- explain in general terms the location of the areas in which coal, metals, and industrial minerals are mined. Further, give examples of specific commodities and where they are mined;

- locate major coal basins in the U.S., and describe one or two characteristics that differentiate the coal regions (other than location);

- explain the relationships between an operating mine and the various public and private stakeholders. List three federal government agencies with a major role in mining and their primary function, two labor unions with significant interest in mining, three national trade associations for mining; and for each of these explain their role;

- cite an example of a state regulatory agency and a state trade association. Explain the relationship between the state and federal entity that has the same general role;

- explain how the U.S. Congress becomes involved in mining and how mining stakeholders interact with Congress;

- explain what is meant by an administrative agency;

- explain the positive benefits of mining in a community or region.

What is due for Module 1?

This module will take us two weeks to complete. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignment below can be found within this lesson.

| Activity | Location | Submitting Your Work |

|---|---|---|

| Read | Pages 1-15 in the course textbook | No Submission |

| Complete |

|

Canvas |

Questions?

Each week an announcement is sent out in which you will have the opportunity to contribute questions about the topics you are learning about in this course. You are encouraged to engage in these discussions. The more we talk about these ideas and share our thoughts, the more we can learn from each other.

Lesson 1.1: Do We Really Need Mining Anymore?

Lesson 1.1: Do We Really Need Mining Anymore?

When I have the opportunity to speak with groups of prospective students or community groups, I enjoy asking a simple question to start the discussion:

When you hear the word mining, do you think past, present, or future? That is to say, is mining an activity that was important in the past, but not so much today, or is it an activity that is currently of some importance, but is becoming less and less important, or is mining an activity of importance now, and which will continue to be important into the future? Let’s see a show of hands… how many of you think past? How many of you think present? How many of you think future when you hear the word mining?

Inevitably, the outcome of this informal survey is the same year after year and group after group! Let’s say we have a hundred prospective students and perhaps some parents in the room as well. Approximately 85 to 90 will raise their hands for past, 5 to 10 for present, and 0 to 5 for future.

This predictable outcome begs for a few follow-up questions, which I am only too happy to ask! OK, let's repeat these three questions, but instead of the word mining, let’s substitute in some other words: food… pharmaceuticals… technology, e.g. solar cells or iPhones… Everyone, i.e., 100% of the audience will respond with future to all of my questions. I need to stop after about the third word because I’ve made my point, and moreover, the audience begins to question my sanity -- after all, what does food have to do with mining!!!

Let’s take a closer look, and let’s start with food. Modern agriculture is heavily dependent on large quantities of mined materials to meet the food needs of an expanding global population. Potash is one of the critical ones and is used to produce fertilizer for crop production and to a lesser extent in feed for livestock. Globally, more than 40 million tons of potash are mined each year, and of that, approximately 2% is mined in the United States. Phosphate is another mined commodity used in food production for fertilizer and feedstock; and of the 260 million tons mined globally, more than 10% is mined in the U.S., Of course, these two commodities, potassium and potash, have other important commercial uses in addition to supporting food production. If for no other reason, mining will be an essential future activity to support agricultural production! No doubt, you already know or are beginning to suspect that there are many, many other needs for mining beyond food production.

There are obvious uses:

- aluminum to make beer cans

- limestone and clay to make cement for producing concrete

- iron for makings steel

- granite for countertops or other architectural applications

- silica sand used as a proppant in fracking operations

And there are the not-so-obvious uses:

- antimony, used in flame retardants

- bismuth, used in medicines

- clay, used to improve the writing texture of paper

- calcite, to make paper a brighter white

- limestone, finely crushed and used (50%) in plastic pipe

- rare earths, used in computers

- titanium, used for sports equipment

- trona, used to make glass

- vermiculite, used in horticulture

- zeolites used for water purification

In the interest of time, let me make a very long story short!

Within the U.S., we have more than 13,000 mines, which mine approximately 85 minerals each year, including the ones listed in the foregoing example. And most of the minerals, including the ones in the list, are used for several purposes. Moreover, mining contributes nearly 2.5 trillion dollars to the U.S. economy. This is about 15% of the U.S. economy; and globally, mining contributes nearly 25% to the world economy!

There was a bumper sticker that came out several years ago: If it can’t be grown, it has to be mined!

Indeed, mined commodities are ubiquitous in modern society, and mining to recover them from the earth’s crust is essential to modern society.

Up to this point, we’ve focused on the nonfuel minerals. We’ve learned about the importance of mining to the national and global economies, the number of mines in the U.S., and the uses for many common and not so common mined commodities. We’ll take a look at where these commodities are mined in Lesson 1.3. Before moving on to this topic, we should look at fuels, and specifically coal and uranium. They constitute another important component of the mining industry, and we'll look at them in the next lesson.

Lesson 1.2: What About the Fuel Minerals?

Lesson 1.2: What About the Fuel Minerals?

In the last lesson, we learned about the many mineral commodities that are necessary to, and ubiquitous in, modern society. We looked at a few of the 85 or so that are mined in this country, and we learned where to find additional detail on many more of these nonfuel minerals. Fuel minerals are another important part of the mining industry.

The fuel minerals are commonly considered to be coal, uranium, oil, and natural gas. Although oil and natural gas extraction are considered mining for certain purposes, e.g., the U.S. Bureau of Labor Statistics, these two commodities are excluded from discussion in this course.

Uranium is mined and processed primarily as a fuel for use in nuclear reactors, which power steam turbines for the generation of electricity. Uranium is mined by underground and surface mining methods, as well as by solution mining. Currently, within the U.S., there are fewer than ten uranium-mining operations, and all use a form of solution mining; although, in years past, it was mined by underground methods in this country, too. Currently, the world’s uranium supply is largely met by a relatively few number of mines. Australia, Canada, Kazakhstan, Namibia, Niger, and Russia count as the biggest producers, supplying more than half of the global need from less than a dozen mines. We’ll talk more about uranium mining later in this course when we learn about solution mining methods.

Coal most commonly is used as a fuel to generate electricity, i.e., it is burned to create heat to power the steam turbines of electric power plants. In more recent years, the use of all fossil fuels, and particularly coal, has come under attack. Airborne pollutants from coal combustion have been dramatically reduced over the years through technological innovation. However, the CO2 produced with the burning of coal is a serious concern. The production of coal has declined dramatically in recent years as aging coal-fired power plants have been retired and replaced with natural gas fired plants. The cost of permitting a new coal-fired plant is prohibitive in the U.S., and as such no new coal-plant capacity is anticipated in the U.S.

Globally, coal-fired plants continue to be built, and the use of coal as a major fuel source continues unabated. Even in the U.S., the level of coal consumption is projected to remain relatively level at 700 million tons per year over the next several decades. Hopefully, research will produce badly needed solutions to the problems associated with the combustion of fossil fuels! Policy and politics aside, as mining engineers we are concerned with the sustainable production of the mineral commodities demanded by society; and, accordingly, we will address the design and operation of coal mines along with the mines to recover the nonfuel minerals.

Although many people think of coal, as coal – a black material that is burned to produce heat, it is a remarkably complex material composed of organic and inorganic compounds, containing 76 naturally occurring elements of the periodic table. Nearly 120 different minerals have been identified in coal, 33 of which occur commonly, and eight or so are major constituents. Some of the trace elements, such as silver, zinc, or rare earths may prove to be a valuable resource, whereas a few others such as cadmium or mercury may be hazardous if concentrated.

Coals are the result of vegetation dying, decaying, and collecting in swamps forming peat bogs, and the subsequent application of heat, and pressure over thousands and thousands of years. The types of plants, the type and amount of foreign materials, e.g., minerals that were blown or washed into these swamps, determines the quality of the coal, as does the amount of heat and pressure that were applied to the peat over eons of time. As mining engineers, and at this early career stage, we don’t need to delve too far into coal science. However, there are a handful of basic concepts that lay a foundation for understanding how and why we mine and process coal in specific ways.

The makeup of the coal, i.e., the organic and inorganic compounds, the minerals, and the macerals affect the combustion properties of the coal, and they affect the options that we have, or do not have, to prepare the coal for a given commercial use. The latter, is known as coal preparation or simply coal prep. The organic origins of the coal are contained in the macerals, and the inorganic materials are contained largely in the minerals. The inorganic materials can generally be removed economically through the coal preparation process, whereas the organic constituents generally cannot. For example, sulfur in the minerals can be removed through crushing and gravity separation operations, whereas the organic sulfur cannot be removed.

Let’s take a short side trip here to discuss coal prep, or the broader term of mineral processing. In the case of coal, our interest is to remove certain impurities that would degrade the value of the saleable product. For example, we typically want to remove mineral matter such as pyrites. The pyrites contribute sulfur and ash, both of which are undesirable, and hence we apply a variety of techniques to separate and eliminate these undesirable components. During the mining process, we may have further contaminated the run-of-mine coal with the rock layers immediately above or below the coal seam. We’ll need to remove these contaminants as well, before shipping the saleable product.

In the case of the nonfuel minerals, such as phosphate or gold, for example, these valuable components will be bound in the ore, and it will usually be necessary to utilize a series of chemical and physical processes to liberate and concentrate the mineral of interest, while separating out the undesirable constituents. The goal of mineral processing is to beneficiate the valuable components of the ore, and mineral processing engineers design the plants and processes to accomplish this goal. It is often said that mineral processing begins at the mining face where the ore is extracted, and as such, the mining engineer becomes directly involved in not only the first stages of mineral processing but also in the overall success or failure of the mining operation! We’ll talk more about this when we look at the selectivity of various mining methods.

Anyway, back to coal, and the undesirable constituents. Why are they undesirable? Clays will tend to foul boilers, making such coals of lower commercial value. Pyrite minerals will break down into iron and sulfur during combustion, and then, upon recombination with oxygen, the iron oxide will form an ash residue, whereas the sulfur dioxide will be discharged as a flue gas. The latter is heavily regulated and there is a cost to trap this sulfur and prevent its release into the environment. Other mineral matter will generally remain in the ash after combustion. This ash must be disposed, and because it may contain hazardous trace elements, the disposal may be expensive. Hence, coals that naturally have fewer minerals, or coals that have been cleaned through a coal preparation plant have a greater economic value. Power companies buy coal for its calorific content, and they have little interest in transporting, handling, and burning a low-BTU coal product!

The discussion so far has focused on the largest market for coal, which is a fuel source to power steam turbines to generate electricity. For commercial purposes, we often categorize coals as either metallurgical or thermal coal. The former is used to make coke for use in steel-making, while the latter is burned to produce heat, and is often called steam coal. Metallurgical coal has several additional properties, and fewer coals meet the more rigorous requirements to be considered of metallurgical quality. Consequently, met coals often sell for double or triple that of steam coal.

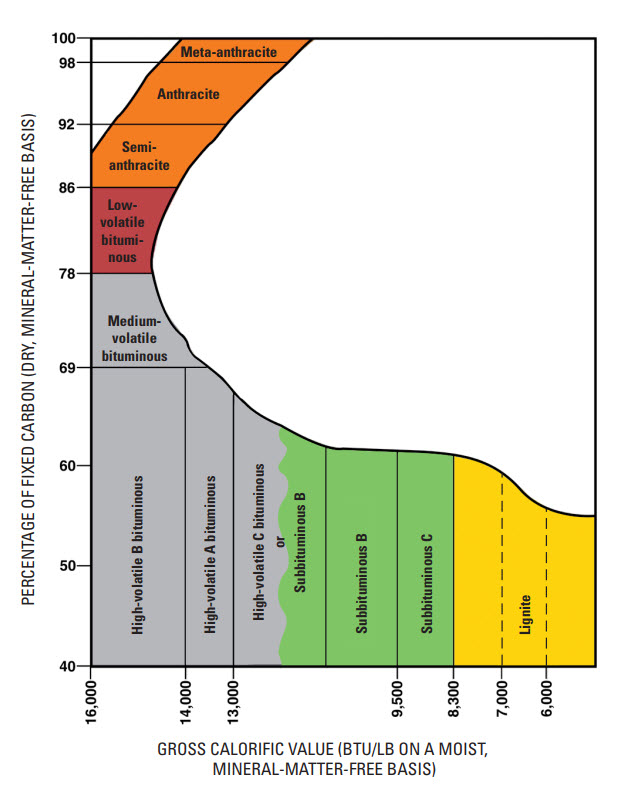

Two very important characteristics of coal are the percentage of fixed carbon and the calorific or heat value of the coal, and these are used to define the rank of the coal, which is a major determinant of the quality of the coal. Coals are classified by rank in the U.S., and there are four ranks. The USGS describes these ranks as follows.

Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbon rich, and harder material. The four ranks are:

- Anthracite: The highest rank of coal. It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high percentage of fixed carbon and a low percentage of volatile matter.

- Bituminous: Bituminous coal is a middle rank coal between subbituminous and anthracite. Bituminous usually has a high heating (Btu) value and is the most common type of coal used in electricity generation in the United States. Bituminous coal appears shiny and smooth when you first see it, but look closer and you may see it has layers.

- Subbituminous: Subbituminous coal is black in color and dull (not shiny), and has a higher heating value than lignite.

- Lignite: Lignite coal, aka brown coal, is the lowest grade coal with the least concentration of carbon.

Reference: Schweinfurth, S.P., 2009, An introduction to coal quality [2], in Pierce, B.S., and Dennen, K.O., eds., The National Coal Resource Assessment Overview: U.S. Geological Survey Professional Paper 1625–F, Chapter C, 16 p.

The figure illustrates the rank of the coal in terms of the two characteristics: calorific value and fixed carbon. As a general rule, coals with higher BTU basis are more valuable in the steam coal market, whereas the fixed carbon content, as well as other properties, is more important to the met coal market. Although we usually think of the selling price of steam coal in terms of dollars per ton, the utility purchasing the coal is thinking in terms of dollars per million BTU.

Before leaving this brief introduction to coal, it is worth noting the many other uses of coal. Already, we’ve identified one use for coal in addition to the most common use. Do you remember this use? If you said coke for use in steel making, you would be correct. Basically, coke is produced by a destructive distillation process in which the coal is packed into an oven and heated to a high temperature in the absence of oxygen. This drives off the volatile matter, leaving a high carbon product required in the manufacture of steel. The lack of oxygen prevents the volatile matter from burning, and if desired, these components can be recovered. As an example, one ton of bituminous coal roasted in an airtight oven will produce 1300 to 1500 lbs. of coke, 8 to 10 gallons of tar, 3 gallons of light oil, 5 to 6 lbs. of ammonia, and 9500 to 11,000 ft3 of gas! The use of coal to produce synthetic fuels, known as synfuel, has a long history going back to WWII and continuing into the present.

Now, with this new knowledge about nonfuel and fuel minerals, we’re ready to talk about a topic that is near and dear to the hearts of miners… just where do we mine these materials, or put another way, where are those 13,000 mines in the United States?

Lesson 1.3: Where Are All of These Mines?

Lesson 1.3: Where Are All of These Mines?

A note about the Figures and Data in this lesson:

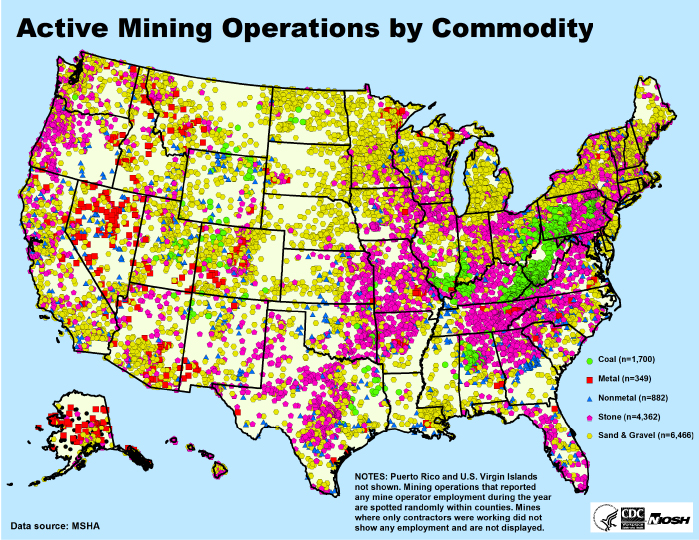

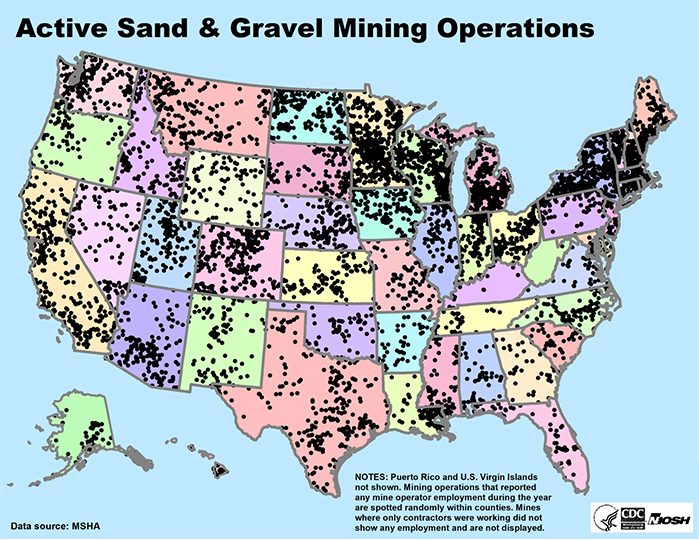

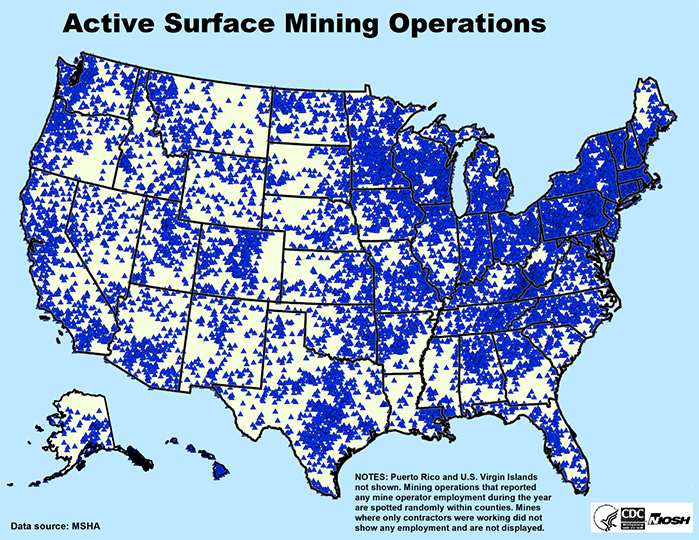

The graphics and data in this lesson are from 2017. Visit this Centre for Disease Control and Prevention/NIOSH Mining [4] interactive website for the latest and most updated information.The most recently available data shows that we have over 13,000 mines in the U.S. By law, all mines must be registered with the U.S. Mine Safety and Health Administration (MSHA), and by analyzing their database, we can learn much about mining in this country. For example, we can determine the number of mines by commodity, size, and location. Back to the question: where are these mines? They’re everywhere, and you probably didn’t realize it! Take a look at Figure 1.3.1 below, which shows the location of these mines by major sector, i.e., metal, nonmetal, and coal.

Before examining this map more closely, we should address the related question: why are they where they are? What do you think?

First and foremost, the availability of the mineral resource will dictate where we mine. Although minerals of nearly every variety are found through the crust of the Earth, it is relatively rare to find a concentration of a particular mineral to justify a commercial mining activity. Of course, the relative rarity of an economic concentration depends on the commodity. If we want to mine gold, for example, there are a limited number of locations where we will find economic concentrations. On the other hand, if we want to mine stone for construction purposes, we can find it almost anywhere.

Let’s say we know of an economic deposit. Are there are other factors that would determine whether or not we would open a mine at that location? Yes, absolutely there are, and we will look at that in more detail later in this course. For the purposes of this discussion, I’ll bring one additional consideration to your attention with the following example. Economic deposits of metals exist in the densely populated areas of the East Coast. Decades ago, there were commercial metal mining activities, e.g., New Jersey Zinc Company. Today, there are none. Why? The land is so valuable that it would be prohibitively expensive to acquire it, and urban zoning ordinances severely restrict mining operations. Now, with this background, let’s take a closer look at the locations of these mines.

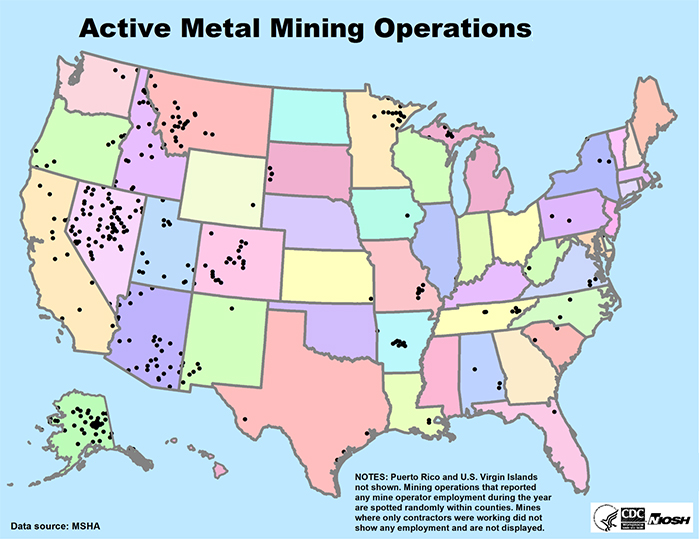

The metal and nonmetal mines encompass the nonfuel minerals. For reasons that may become clear as we go through this course, a variety of terms, which are similar if not synonymous, are used by geologists, mining engineers, and government regulators. Anyway, the location of the metal/nonmetal mines is shown in Figure 1.3.2.

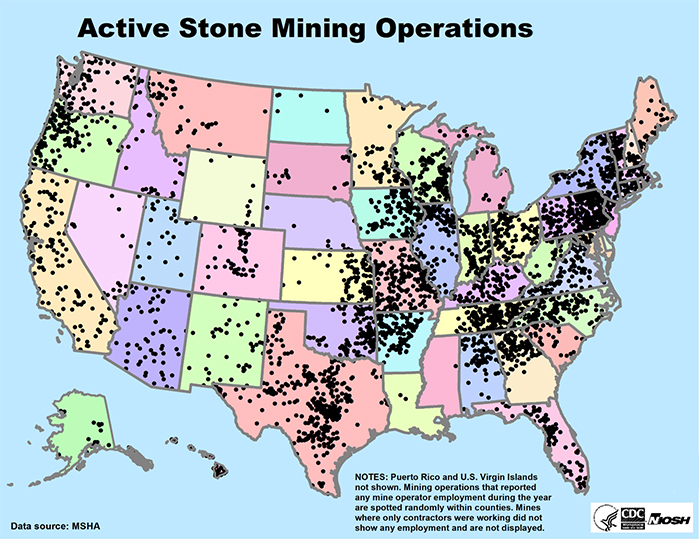

We can go down one additional level, and separate the metal from the nonmetal mines, as shown in Figures 1.3.3 and 1.3.4.

Stone, sand, and gravel mines are generally grouped together and are separated from metal/nonmetal mines, even though these commodities qualify as nonmetal. For clarity, the stone mines are shown separately from the sand and gravel mines in Figures 1.3.5 and 1.3.6. As you can see, the number of mines is remarkably large. They are everywhere! Why are they everywhere? Simply, several different minerals can be used as aggregates, i.e., stone, sand, and gravel; and as such, they are readily found throughout the U.S. Just because we have a mineable deposit, do we have a need for a mine? No! What else do we need? There must be a demand for whatever we are going to mine, i.e., we need a market for the mined product. Aggregates are used for what purpose? The primary use is in construction – construction of houses, buildings, roads, and so on. Thus, there is a strong demand for aggregates wherever people live and work, and this is evident from the maps.

1.3.1: Where Are All of These Mines? Continued

1.3.1: Where Are All of These Mines? Continued

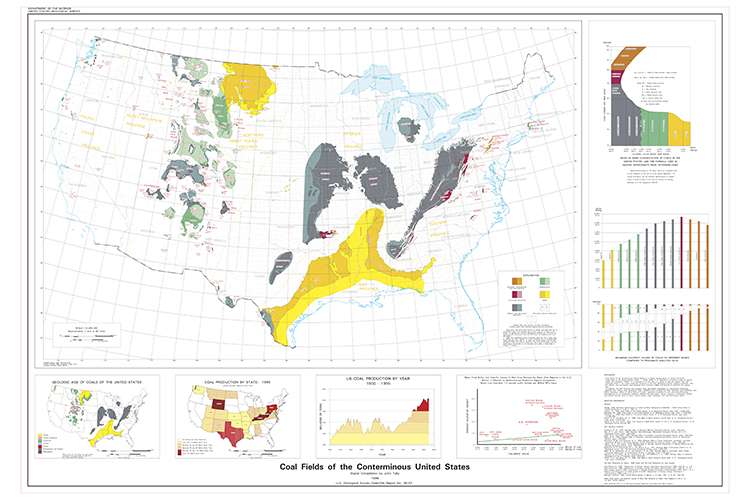

Next, let’s look at the fuel minerals, and specifically coal. After looking at Figure 1.3.7, examine the USGS map of U.S. coalfields in Figure 1.3.8. Do you see the correspondence between the coalfields and the location of coal mines? There is a lot of detail to be gleaned from this figure, and I suggest you zoom in and take a closer look. Take note of the rank of the coal found in the different coalfields, and also note the relatively few locations in which metallurgical-grade coal is found.

These figures that we’ve just examined are helpful as we endeavor to learn major characteristics of the U.S. mining industry. There are many ways to “slice and dice” the available data, depending on your specific interests.

1.3.2: Where Are All of These Mines? Continued

1.3.2: Where Are All of These Mines? Continued

In this lesson, I want you to look at a few additional representations. The Mineral Commodity Summaries [9] are published on an annual basis. This report is the earliest Government publication to furnish estimates covering nonfuel mineral industry data. This publication will break out in more detail the major metal and nonmetal (industrial mineral) mining regions by commodity. Spend some quality time reading and analyzing the Mineral Commodity Summaries to view the figures of the relative economic value or significance of mining in specific regions. The economic value of metals mined in the U.S. is shown by region. We can examine industrial minerals in the same fashion, starting this time with the economic value of industrial minerals production by state. We can then go to a more detailed commodity map to see not only the location at which the major industrial minerals are mined, but also which ones are contributing to the economic value within a given state or region.

Finally, I would close this discussion that has focused on the location of mining activity with a different perspective on the location of mines. We now understand the geographic dispersion of mining activity as well as the concentration of mining in certain areas for certain commodities. A different twist to the question, where are these mines?, is: are these mines located on the surface or are they deep beneath the surface? Figures 1.3.9 and 1.3.10 clearly show that most mining occurs in surface rather than underground mines, by a ratio of nearly 15:1. We’ll examine the reasons for this later in the course, but an important point now is that most of these mines are located on the surface.

In this lesson we’ve learned where the fuel and nonfuel minerals are mined, and we’ve developed a better understanding of the extent of mining activities. Soon, we will be ready to look at the life cycle of mining operations and the engineering associated with each part of the cycle. Prior to doing so, there is one last overarching topic to cover, and that is mining in today’s world.

Lesson 1.4: Mining in Contemporary Society

Lesson 1.4: Mining in Contemporary Society

Once upon a time, a mining operation was opened with little more than a mule, a pickaxe, a shovel, and some camping supplies, and of course a crusty old guy with a floppy hat! Alas, the world has become much more complicated, and opening and operating a mine has become a complex undertaking. In the early stages, the mining engineers may well be part of a team consisting of professionals from archeologists to zoologists! Really, I am not joking! Before we delve into the details of designing and operating mines, we’ll be well served with a basic understanding of the broad context in which mining occurs today, i.e., the interactions between the mine or mining company and other elements of society. Let’s start with that piece in this lesson.

Slideshow Review

Review the MNG 230 PDF of Slideshow [10]. This includes valuable information that will support your learning throughout the remainder of the lesson.

The diagram that we constructed in this lesson captures the workings of real-world mining; and for those of you who will work in this industry in an engineering or science capacity, you will experience many of these interactions very early in your career and throughout your career. Moreover, an understanding of the societal context in which mining occurs will help you to understand why we follow certain practices, or why we are limited in our approaches. Beyond that, this lesson has served as a platform to introduce you to key stakeholders in the mining industry. A mining stakeholder is a person or organization that either affects the mining operation or can be affected by the mining operation. Given our discussion here, I think you will agree that the organizations represented in our diagram are very important stakeholders. If we were to attempt a list of all stakeholders, it would be very long and include manufacturers, universities, consultants, contractors, and on and on. Arguably, there is one significant stakeholder missing from the diagram: Non-Governmental Organizations, known as NGOs. An NGO is an organization that is independent of governments, is funded through donations, and has a specific mission, e.g., protect the environment. In particular, there are many NGOs at the regional, national, and international level with missions that are in conflict with mining. For example, some NGOs operate on the belief that there should be no extraction of resources for any purpose, while others have a primary interest of ensuring no damage to the environment. Others seek the elimination of fossil fuel usage. Regardless of your politics and beliefs, NGOs are a reality. Through often-frivolous lawsuits, and civil disobedience that borders on or crosses over into criminal behavior, NGOs are important stakeholders in mining. The solution to this represents one of the grand challenges that will be discussed in this course.

Module 1 Summary

Module 1 Summary

An important goal of this module has been to give you a broad background on mining and the mining industry -- why we mine, the kinds of things we mine, where we mine, and the stakeholder groups with an interest in what we do. A general understanding of the many mined commodities, their use and importance, and the locations where these minerals are found will be helpful as we begin to study the life cycle of a mine. Similarly, the influence of the stakeholders permeates many of the processes in the stages of the life cycle, and with knowledge of these stakeholders and their role, you will understand better why we do certain things in ways that might not be entirely obvious! Moreover, you will interact on a regular basis with many of the stakeholders that you learned about, and the more you understand of their role, the more effective you will be in your job.