Lesson 9.2: Elements of Underground Mines

Lesson 9.2: Elements of Underground Mines

Underground mines share common elements regardless of the specific mining method. Examples include pillars, stopes, and drifts. It is necessary to understand these words and to use them correctly. Perhaps the most onerous task in this course is to memorize these definitions. There’s simply no way around it. You have to memorize them and understand conceptually what they mean. You’ve done already for a variety of terms including burden, spacing, highwall, and box cut, among many, many others. The difference here is that you are being hit with a relatively large number of terms all at once. Of course, if you heeded my advice earlier in the semester, then you have been memorizing a few of these each week, and now you are in good shape! I won’t ask if you’ve done that…

Let’s dive into the definitions!

The text divides the definitions into three broad categories.

Deposit and Spatial

These terms are useful to describe the deposit and major features that define the mine within the deposit.

Directional

These terms allow us to communicate the relative location of something within the mine, or the direction in which an activity is moving.

Excavation

These terms capture the features that we create within the deposit through our mining activity.

I am not going to ask you to tell which terms fall into which category. I’m only trying to explain the underlying rationale for the groupings. Some terms are rarely used or are specific to just a few uncommon mining methods. I’ll try to distinguish those from the ones that are used widely. Obviously, you will want to know the latter quite well! I recommend that you read through the terms, and then refer to the three figures that follow to help understand the meaning of the terms, and then go back to the definitions with the goal of memorizing them. Ok, with this out of the way, let’s get to it!

9.2.1: Deposit and Spatial Terms

9.2.1: Deposit and Spatial Terms

If we are in a horizontal deposit and we mine an opening into the deposit, that opening will have a top and a bottom. We often use those terms. We might say, “this mine has good top,” and we mean that the rock structure at the top of the opening is competent. Or, we might say, “that seam is underlain by clay, and the bottom is terrible,” and we mean that it is difficult for equipment to move around because of the poor condition of the bottom. In a tabular deposit, we frequently refer to the top as the roof, and the bottom as the floor. Conceptually, this aligns with our everyday experiences – if someone refers to the roof or the floor, we know what they mean. Likewise, if we refer to the top or bottom of our mined opening, we intuitively know what is meant. As I indicated, these four terms, top, bottom, roof, and floor, work well for tabular deposits, and are used in coal, trona, potash, salt, and stone mines, for example.

When we move into metal mines, we will not hear those terms. There are a few reasons for this. The mining methods and culture evolved differently in metal versus coal and some of the nonmetals, and they each evolved their own terminology. It’s similar to the situation with the word we use to describe a soft drink. In some parts of the country we would ask for a bottle of “pop.” In another region, we would request a bottle of “soda.” If you go into an area and use the “wrong” term, people may snicker and smile, but they will know what you mean. The same is true for some of these mining terms, except that in addition to smiling, they will likely think that you are a rookie and perhaps are not really a mining person. If, in fact, you are a mining engineer, then that would not be a good thing!

The second reason for the difference in terms relates to the spatial complexity of many metal mines and metalliferous the deposit. In a steeply dipping deposit, for example, the concept of a roof and floor is less useful than hanging wall, footwall, and back. And, of course, there can be crossover in terms. A mining engineer working in a tabular limestone deposit will refer to the top of the opening as the roof, unless they have a background in the metal industry, and then they will refer to it as the back. Don’t despair! As you look at the figures, study the definitions, and read more about the methods, it will become perfectly clear. On with the definitions!

- Top: Overlying surface of an underground excavation.

- Bottom: Floor or underlying surface of an underground excavation.

- Roof: Top or overlying surface of an underground excavation.

- Floor: Bottom or underlying surface of an underground excavation.

- Back: Roof, top, or overlying surface of an underground excavation.

- Country rock: Waste rock adjacent to a mineral deposit; and sometimes called host rock.

- Wall rock: Country rock boundary adjacent to a deposit.

- Footwall: Wall rock under the deposit.

- Hanging wall: Wall rock above a deposit.

Initially, students are uncertain about which is the footwall and hanging wall. If you have doubts, remember this: these two terms only have meaning if the deposit is dipping at an angle; and pretend the opening in the deposit is a sliding board, and that you are going to slide down – and when you do, your butt will ride on the footwall. Now you’ve got a silly but effective way to keep it straight. Speaking of the footwall, you will notice that the shaft and the workings are located in the country rock and on the footwall side of the deposit, not the hanging wall. There’s a good reason for that. Why do you think that is the case?

All right, onward with the definitions! Here are two more of major importance.

- Dip: Angle of inclination of a deposit, measured from the horizontal; also pitch or attitude.

- Strike: Horizontal bearing of a tabular deposit at its surface intersection.

We’ve talked on various occasions about deposits that dip, and so you already have a familiarity with the term. A synonym that is sometimes used is pitching. The terms steeply pitching or a steeply dipping are synonymous. This is true whether it is a seam, vein, deposit, or orebody.

If you’re a surveyor or a geologist, then you are very familiar with the concept of strike. The dip of a deposit can have a profound impact on the type of mine that we develop, but not so for the strike! The strike provides us a direction on the compass to orient our workings, but little more than that for the mining engineer. Now, for structural and economic geologists… they can get excited by the strike of the vein!

In the process of excavating an opening, i.e., mining, we will often leave behind sections of the orebody, for the sole purpose of providing structural support to the overlying layers of rock. These unmined blocks are called pillars, and they are necessary to prevent a collapse of the mined openings. Certain pillars are given specific names, as follows.

- Pillar: Unmined portion of the deposit, providing support to the roof or hanging wall.

- Crown pillar: Portion of the deposit overlying an excavation and left in place as a pillar.

- Sill pillar: Portion of the deposit underlying an excavation and left in place as a pillar.

- Barrier pillar: a pillar designed to withstand major loads.

- Yield pillar: a pillar designed to yield, but not fail under heavy loads.

Crown and sill pillars are commonly found in mines for steeply pitching deposits, and barrier and yield pillars are commonly found in tabular deposits that are nearly horizontal.

Finally, within this first group, three more terms:

- Capping: Waste rock overlying the mineral deposit.

- Rib: Side wall of an excavation.

- Gob: Broken, caved, and mined-out portion of the deposit. Often, mined out areas will begin to cave, and this is a normal part of the process. The caved area is known as the gob, or in some parts of the world, the goaf.

9.2.2: Directional Terms

9.2.2: Directional Terms

The directional terms are quite useful and not too difficult to remember. Let me give you an example to illustrate these terms before I give you the formal definition. Imagine that we are all in a big classroom, and the classroom represents the mined out opening. This classroom has rows of chairs and then near the front of the room there is a table on which I lay my books and materials, and then we have a chalkboard on the front wall. I stand behind the table to lecture. There is a door into the classroom on the rear wall. Got the picture?

Ok, let’s imagine that we are mining in the direction of the chalkboard, i.e., we are advancing in the direction of the chalkboard. We’re going to drill holes into the chalkboard, load the holes with explosives, blast, and load out the broken material. We’ve just made the classroom bigger! The chalkboard where we drilled and blasted is known as the face or working face. It is also known as the breast. The act of mining in this horizontal direction is known as breast stoping.

Now, let’s suppose that I’d like to make the classroom higher rather than longer. So, I am going to drill holes into the ceiling, load the holes with powder, shoot them, and load out the broken material. When I advance in this upward direction, it is said to be overhand stoping. Similarly, if I wanted to enlarge our classroom to a lower level, I would drill down into the floor, blast, and load the broken material. When I advance in a downward direction, it is called underhand stoping.

Finally, I can squeeze one last example out of this classroom setting to help you understand the terms inby and outby. These two terms are very useful to state a relative position. Typically, the relative position is between the working face and the entrance to the mine or some portion of the mine. In our classroom that we are pretending is a mine opening, we have a working face (chalkboard wall) and an entrance (the door in the rear wall). Remember the table near the front of the room. If I am standing behind the table, close to the chalkboard, I am standing inby the table, and you are sitting outby the table. If we had a video camera set up in the fourth row back, the students in rows one through three would be sitting inby the camera, and the students sitting in row five to the back of the room would be sitting outby the camera.

This business of inby and outby may seem a little strange, but these words are extremely useful. There is for example, a regulation that prohibits miners from working inby the last row of roof bolts. Or another that allows certain electrical equipment to be used only if it is outby the last open crosscut. Hopefully, with this example, the following terms will be clearer.

- Breast: Advancing in a near-horizontal direction, also the working face of an opening.

- Inby: Toward the working face, away from the mine entrance.

- Outby: Away from the working face, toward the entrance.

- Overhand: Advancing in an upward direction.

- Underhand: Advancing in a downward direction.

9.2.3: Excavation Terms

9.2.3: Excavation Terms

These terms describe the types of openings that are created to facilitate mining of the deposit. The adjectives primary, secondary, and tertiary are used to characterize some of the terms. This is to indicate the relative importance of the opening in the same sense as saying interstate highways are primary roadways, two-lane streets in a city are secondary roadways, and the alleys between some streets are tertiary roadways. Some of these terms are specific to certain mining methods, and when we study those methods, they will become clearer. I want you to understand all of them, but for right now, focus on the ones that I have highlighted in red.

- Bell: Funnel-shaped excavation formed at the top of a raise to move bulk material by gravity from a stope to a drawpoint.

- Bleeder: Exhaust ventilation lateral.

- Chute: Opening from a drawpoint, utilizing gravity flow to direct bulk material from a bell or orepass to load a conveyance.

- Crosscut: Tertiary horizontal opening, often connecting drifts, entries, or rooms; oriented perpendicularly to the strike of a pitching deposit; also breakthrough.

- Drawpoint: Loading point beneath a stope, utilizing gravity to move bulk material downward and into a conveyance, by a chute or loading machine; also boxhole.

- Drift: Primary or secondary horizontal or near-horizontal opening; oriented parallel to the strike of a pitching deposit.

- Entry: Secondary horizontal or near-horizontal opening; usually driven in multiples.

- Finger raise: Vertical or near-vertical opening used to transfer bulk material from a stope to a drawpoint; often an interconnected set of raises.

- Grizzly: Coarse screening or scalping device that prevents oversized bulk material from entering a material transfer system; constructed of rails, bars, beams, etc.

- Haulageway: Horizontal opening used primarily for materials handling.

- Lateral: Secondary or tertiary horizontal opening, often parallel or at an angle to a haulageway, usually to provide ventilation or some auxiliary service.

- Level: System of horizontal openings connected to a shaft; constitutes an operating horizon of a mine.

- Loading pocket: Transfer point at a shaft where bulk material is loaded by bin, hopper, and chute into a skip.

- Manway: Compartment of a raise or a vertical or near-vertical opening intended for personnel travel between two levels.

- Orepass: Vertical or near-vertical opening through which bulk material flows by gravity.

- Portal: Opening or connection to the surface from an underground excavation.

- Raise: Secondary or tertiary vertical or near-vertical opening, driven upward from one level to another.

- Ramp: Secondary or tertiary inclined opening, driven to connect levels, usually in a downward direction, and used for haulage.

- Room: Horizontal exploitation opening, usually in a bedded deposit.

- Shaft: Primary vertical or near-vertical opening, connecting the surface with underground workings; also vertical shaft.

- Slope: Primary inclined opening, usually a shaft, connecting the surface with underground workings.

- Slot: Narrow vertical or inclined opening excavated in a deposit at the end of a stope to provide a bench face.

- Stope: Large exploitation opening, usually inclined or vertical, but may also be horizontal.

- Sublevel: Secondary or intermediate level between main levels or horizons, usually close to the exploitation area.

- Transfer point: Location in the materials-handling system, either haulage or hoisting, where bulk material is transferred between conveyances.

- Tunnel: Main horizontal or near-horizontal opening, with access to the surface at both ends.

- Undercut: Low horizontal opening excavated under a portion of a deposit, usually a stope, to induce breakage and caving of the deposit; also a narrow kerf cut in the face of a mineral deposit to facilitate breakage.

- Winze: Secondary or tertiary vertical or near-vertical opening, driven downward from one level to another.

If you haven’t done so already, this would be a good time to look at the figures.

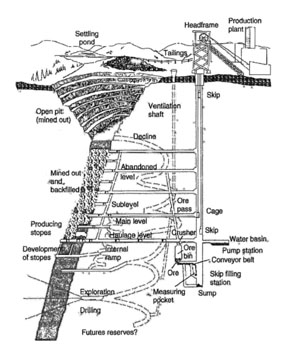

This figure from the text illustrates the basic infrastructure for a mine in a steeply pitching deposit. Generally, these mines are spatially complex.

The footwall and hanging walls are not labeled, but I am sure you can identify them after our previous discussion. The answer to the question of why the permanent structures such as the shaft are located in the footwall side of the deposit is: as areas are mined out within the deposit, it is likely that some caving will occur, and the caving can be a consequence or cause of fractures propagating through the hanging wall, and potentially ending at the surface. If there were any structures such as a shaft in the hanging wall of the deposit, they would be destroyed by the normal mining operation.

You’ll note the main levels versus the sublevels, and don’t miss the decline. Also, take note of the exploration-drilling program that is ongoing throughout the life of the mine.

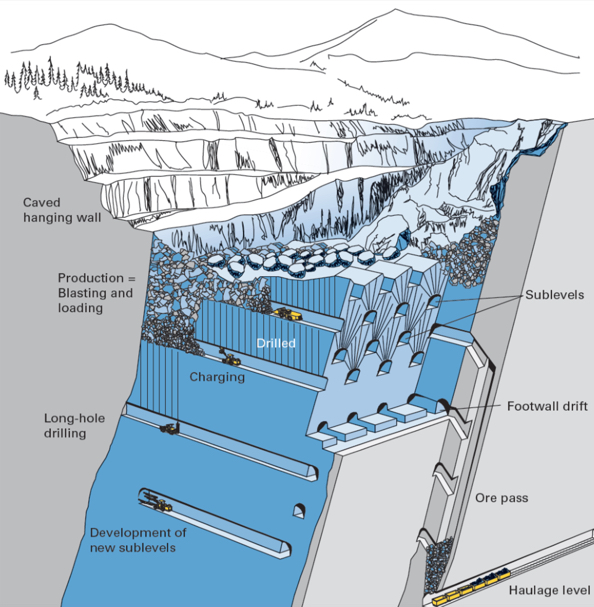

I like the next figure because it shows the footwall drift clearly as well as the sublevels and some of the unit operations within the sublevels. The ore passes down to the haulage level are easy to see in this figure, too.

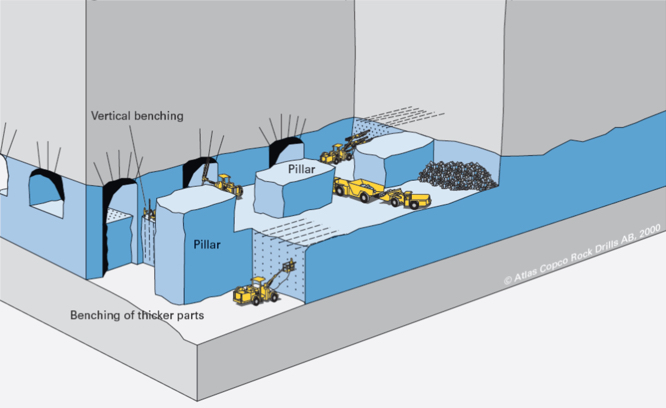

Finally, this third figure allows me to illustrate and elaborate on more of the terms. In thick-bedded deposits, it is often necessary to mine the bed in multiple steps known as lifts or benches. In this example, they are taking the seam in two lifts, and you can see the work underway on the benches. Specifically, you should be able to identify the locations where they are breast stoping, underhand stoping, and overhand stoping. You can also see the pillars that are being left behind to support the overlying strata.

Now that we have a common vocabulary to describe the elements of underground mines, as well as an understanding of these basic elements, we are ready to look at the underground mining methods. In the next two lessons, we will look at the methods. I think it is useful to put the methods into a context of their usage within the industry. That is to say, some methods are rarely applied, and others are frequently applied. Let’s finish up this lesson by taking a closer look at this.

9.2.4: Prevalence of Underground Mining Methods

9.2.4: Prevalence of Underground Mining Methods

The actual number of underground mines will fluctuate somewhat year-to-year, as a few close and a few open. In recent years, there has been a more significant shift in the number, as several underground coal mines closed due to market conditions. Even though the actual numbers will vary, the proportions are relatively stable. For the purposes of this illustration, we will use underground mines in the U.S., and I’ll round up the number slightly for ease of comparison. There are approximately 600 underground mines in the U.S. Of those, approximately 400 are coal and approximately 200 are noncoal. The noncoal includes metals, industrial minerals, and stone mines.

Every one of the 400 coal mines utilizes the room and pillar method, neglecting the 2 or 3 underground anthracite mines that employ a hybrid method. All of the other underground mining methods are distributed among the 200 noncoal mines. Let’s look at that group in more detail.

| Unsupported Methods | Supported Methods | Caving Methods |

|---|---|---|

| Room and Pillar (150) | Cut and Fill (including sub-methods/variations (23) | Block Caving (2) |

| Shrinkage Stoping (2) | Sublevel Caving (0) | |

| Open Stoping (including sub-methods/variations) (18) | Longwall (all of the longwalls, coal and noncoal, are in mines that use room and pillar for the development of the panels) |

The disproportionate number of room and pillar mines is quite noteworthy. Roughly 75% of the underground noncoal mines employ this method. If you add the coal mines into the mix, roughly 90% of all underground mines are using the room and pillar method. Let me ask you a question. If you were to become an expert in the design of one mining method, which would you choose? Well, certainly your career options would be much better if you chose room and pillar! This is not to say that you don’t need to learn about the other methods! You do!!! However, in our curriculum, we do emphasize this method more than the others, and now you know why!

Let’s look at the commodities mined by the three most prevalent methods: room and pillar, cut and fill, and open stoping; as well as the two rarely used methods (in this country) of shrinkage stoping and block caving.

| Method | Commodity | Number |

|---|---|---|

| Room and Pillar | Limestone & Gypsum | 105 |

| Salt | 16 | |

| Lead/Zinc | 12 | |

| Trona | 5 | |

| Potash | 4 | |

| Silver/Gold | 3 | |

| Copper | 1 | |

| Open Stoping | Gold | 9 |

| Zinc | 7 | |

| Nickel | 1 | |

| Platinum | 1 | |

| Shrinkage Stoping | Gold | 2 |

| Cut & Fill | Gold | 19 |

| Silver | 2 | |

| Platinum | 2 | |

| Block Caving | Molybdenum | 2 |

Please be aware that not all commodities are accounted for in this table. There are additional industrial minerals mined by an underground method, which are not accounted for in this data. Despite the very small discrepancies in the totals, the data illustrates accurately the prevalence of the mining methods by commodity.

Review your knowledge of Module 9 terms by engaging with the interactive activities.