Module 8 Overview

The vast majority of minerals, by tonnage and type, are recovered from surface mining activities. As you know, surface mining is used to recover near-surface mineral deposits, where it is economically feasible to remove the overburden to gain access to the minerals of interest. Surface mining is typically a large scale and bulk operation. In general, the surface mining methods are the lowest cost of any mining methods. Of course, some minerals of economic interest lie too deep to be economically recovered by a surface method, whereas others cannot be mined by a surface method because of environmental or social constraints, which necessitate using an underground mining method to recover those deposits.

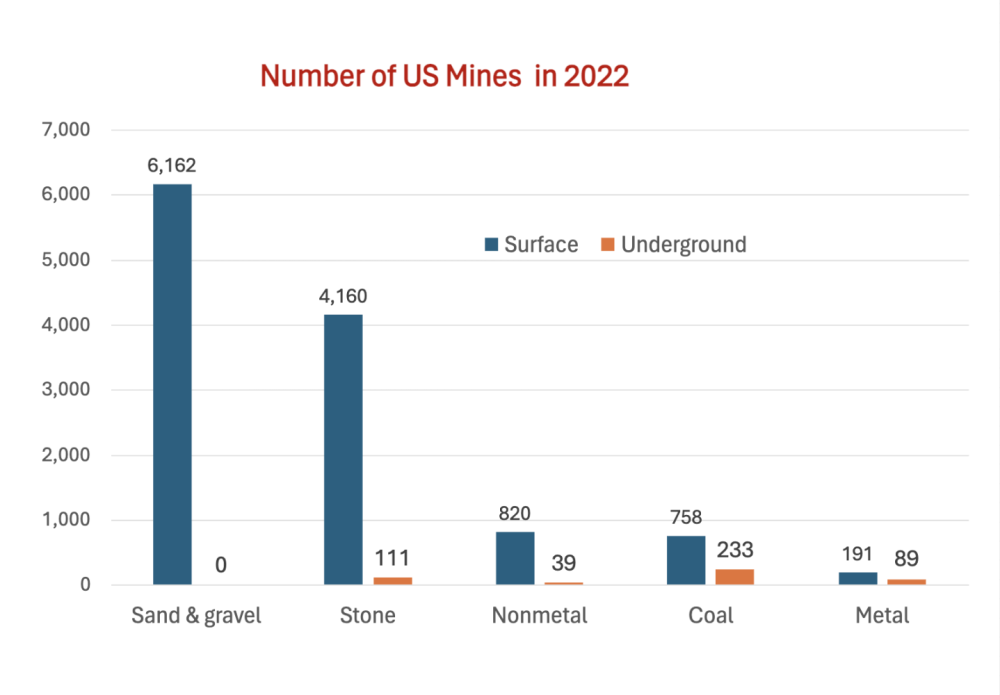

Let’s take a look at the number of surface vs underground mining operations for each mining sector in the US.

Click to expand to provide more information

Not only are there more surface than underground mines, but also the average productivity is higher for surface operations. The average productivity (average tons per miner per hour) for surface mining is around three times the value for underground mining. Here is a summary of coal mine productivity for different years (the values are tons per miner per hour) to illustrate the difference in productivity, as well as changes that have occurred over the years.

| Year | Underground | Surface | All Mines |

|---|---|---|---|

| 1980 | 1.21 | 3.27 | 1.93 |

| 1990 | 2.54 | 5.94 | 3.83 |

| 2000 | 4.15 | 11.01 | 6.99 |

| 2010 | 2.89 | 9.47 | 5.55 |

| 2015 | 3.45 | 10.95 | 6.28 |

The depth and breadth of engineering required for surface as compared to underground mining is arguably significantly less. Nonetheless, good engineering is the key to sustainable operations; and it all begins with mine planning.

Learning Outcomes

At the successful completion of this module, you should be able to:

- demonstrate knowledge of the goals of long-range, short-range, and production planning;

- demonstrate an understanding of the Mathieson list of objectives for the extraction planning process, and explain in specific terms how those objectives would affect planning and mining activities;

- lay out a bench for an open pit mine, labeling the toe, crest, the face angle, bench width and height, face angle, slope or pit angle, and the berm location and height. Describe the parameters and considerations that will affect the design of the bench;

- demonstrate knowledge of the mechanical and aqueous surface mining methods, and specifically for each method:

- describe the factors that favor the choice of the method over other methods,

- describe the life cycle and sequence of operation,

- sketch the method to illustrate its defining characteristics,

- list the type of equipment normally associated with the method, and

- name examples of commodities that are commonly mined using the method.

What is due for Module 8?

This module will take us two weeks to complete. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignment below can be found within this lesson.

| Activity | Location | Submitting Your Work |

|---|---|---|

| Read |

|

No Submission |

| Complete |

|

Canvas |

Questions?

Each week an announcement is sent out in which you will have the opportunity to contribute questions about the topics you are learning about in this course. You are encouraged to engage in these discussions. The more we talk about these ideas and share our thoughts, the more we can learn from each other.